What Happens If Your Safety Signage Isn’t Compliant?

Date Posted:15 August 2025

Safety signage compliance is more than a legal requirement—it’s a lifeline in emergencies. Discover the real risks of non-compliance and how you can protect your workplace today.

Verdex Insights: At a Glance

-

The Challenge: Many workplaces overlook or misuse safety signage, leaving critical areas under-communicated and non-compliant. Poor or missing signs can cause confusion, increase accident risk, and expose businesses to WHS penalties or insurance issues.

-

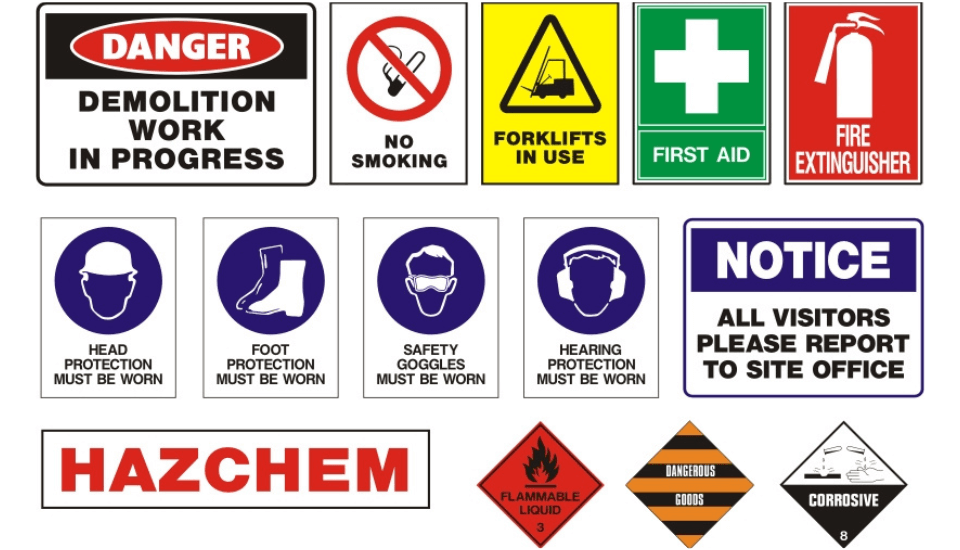

The Insight: Compliant signage under AS 1319:1994 ensures hazards, exits, and mandatory actions are communicated clearly. Using correct colours, symbols, and placement helps prevent injuries, maintain order, and support legal compliance across all worksites.

-

The Verdex Solution: Verdex supplies WHS-compliant workplace safety signage and information systems for warehousing, construction, manufacturing, and logistics sectors. Our durable, regulation-ready signs help businesses meet compliance, prevent incidents, and reinforce strong safety culture across every site.

Why Safety Signage Compliance Matters

Safety signage in the workplace isn't just for decoration, it’s a life-saving communication tool. From guiding emergency exits to warning about hazardous machinery, signs deliver critical information at the exact moment it's needed.

Compliance with signage standards helps prevent workplace injuries, confusion, and panic. It ensures that all staff, contractors, and visitors are aware of risks and understand the correct actions to take in specific zones.

When signs are missing, incorrect, or unclear, the likelihood of accidents increases and so does the liability. Non-compliance with national standards doesn’t just put people in danger; it puts your business operations, reputation, and legal standing at risk.

Proper workplace signage and information forms the foundation of a strong workplace safety culture and shows your commitment to WHS obligations under Australian law.

What Is Considered ‘Compliant’ Safety Signage in Australia?

In Australia, compliant safety signage must adhere to AS 1319:1994—the standard that outlines the design, use, and placement of safety signs in occupational environments.

Key compliance features include:

-

Correct colours: Red for danger, yellow for warning, blue for mandatory actions, green for emergency information

-

Appropriate symbols: Pictograms must be universally understood

-

Visibility: Signs must be easy to read from a safe distance, with sufficient lighting or contrast

-

Durability: Materials must withstand conditions such as UV, moisture, or impact

-

Placement: Signs must be located where the risk exists and not be obstructed or hidden

Homemade or off-brand signs often fail to meet these criteria, leaving businesses vulnerable to WHS breaches and diminished safety communication.

At Verdex, we have a wide selection of compliant signage to keep your workplaces in-line with WHS regulations. For additional precautions, make sure to supply your staff with relevant PPE clothing and safety gear, as well as reliable first aid equipment to assist all types of accidents that may occur in the workplace.

Consequences of Not Having Compliant Signage

Legal Penalties & WHS Breaches

Failing to comply with signage requirements can result in serious legal consequences under Work Health and Safety (WHS) laws. Regulators such as Safe Work Australia or state authorities may issue fines, penalties, or improvement notices.

Repeat or serious breaches (especially those that result in injury) can lead to:

-

Hefty fines exceeding $100,000 for businesses

-

Prosecution of responsible officers or directors

-

Stop-work orders or site shutdowns

In addition, non-compliant signage can invalidate insurance claims, particularly if the lack of correct warning signs contributed to an incident. It’s a risk that no business can afford.

Increased Risk of Workplace Incidents

Incorrect, missing, or poorly placed signage increases the risk of injury—especially in high-risk industries like warehousing, logistics, construction, and manufacturing.

Examples include:

-

A worker entering a confined space without knowing due to the absence of a “Danger” sign

-

Staff failing to wear PPE where required because there’s no “Mandatory PPE” sign

-

Unmarked slip hazards or vehicle zones causing preventable injuries

Signage is a form of visual communication. When that communication fails, it exposes everyone on-site to harm.

Operational Downtime

Non-compliance can also cause costly operational delays. An incident resulting from unclear signage may lead to:

-

Regulatory investigations

-

Temporary shutdowns

-

Time-consuming WHS audits or reviews

-

The need to remove and replace incorrect signage across the site

Even minor signage breaches found during an audit can lead to project delays, contract disputes, or mandatory rectification works. Investing in correct signage from the outset saves time and prevents expensive rework.

Reputational Damage

Workplace safety performance directly impacts your business reputation. News of WHS breaches or preventable injuries, especially those linked to signage failure, can quickly spread.

Consequences include:

-

Losing client trust and credibility

-

Reduced competitiveness when bidding for contracts (especially in construction or government sectors)

-

Difficulty attracting and retaining staff, as poor safety culture affects morale

Safety signage is a small detail that carries a big message: We value safety. Failing to meet signage obligations undermines that message.

Common Areas Where Signage Non-Compliance Occurs

While many businesses make an effort to install safety signs, compliance gaps are still common. These include:

-

Missing signs for fire exits, first aid stations, or hazardous zones

-

Incorrect colours used on homemade signs (e.g., using yellow for mandatory actions)

-

Faded, damaged, or peeling signs that are no longer legible

-

Lack of multilingual signage or pictograms in culturally diverse workplaces

-

Temporary printed signs used in place of proper, compliant signage

These issues can quickly escalate during an audit or emergency event. Regular reviews help ensure that signage remains effective and compliant.

How to Check If Your Workplace Is Compliant

To stay on top of safety signage compliance, follow this checklist:

-

Conduct a signage audit with a WHS officer or safety consultant

-

Compare all signage to AS 1319:1994—pay attention to colour, shape, and messaging

-

Confirm placement: Signs should be at eye level, unobstructed, and where the risk occurs

-

Replace faded, broken, or non-compliant signs immediately

-

Use high-visibility materials (aluminium, corflute, polypropylene, or adhesive backing) suited to indoor or outdoor use

At Verdex, we offer signage audits and tailored safety solutions that ensure your workplace is compliant and ready for inspection. For added protection between staff and hazardous areas, implementing safety barriers and security bollards can help reduce risk.

If you require any assistance, get in touch with the team at Verdex by:

-

Emailing sales@verdex.com.au

-

Filling out our contact form

Frequently Asked Questions

What is AS 1319:1994?

AS 1319:1994 is the Australian Standard for occupational safety signage. It defines how signs should be designed, coloured, and positioned to effectively communicate hazards and instructions in the workplace.

Can I create my own signs with a printer or label maker?

No. DIY signage rarely meets the design, material, or visibility standards set by AS 1319:1994. It’s best to use professionally produced signage that’s durable, legible, and compliant.

How often should signage be checked or replaced?

We recommend a signage audit every 6–12 months. You should also check signs after workplace changes, renovations, or incidents. Replace any that are damaged, faded, or no longer relevant.

Do all signs need to be in colour?

Yes. Colours are a critical part of safety communication. Red, yellow, blue, and green each have specific meanings under AS 1319:1994 and help workers quickly identify the nature of the message.

Trolleys & Hand Trucks

Trolleys & Hand Trucks Cage Trolleys

Cage Trolleys Cleaning Carts & Trolleys

Cleaning Carts & Trolleys Construction Trolleys

Construction Trolleys Custom Trolleys

Custom Trolleys Hand Trucks & Dollies

Hand Trucks & Dollies Laundry/Linen Trolleys

Laundry/Linen Trolleys Lifting Trolleys

Lifting Trolleys Order Picking Trolleys

Order Picking Trolleys Panel Cart Trolleys

Panel Cart Trolleys Platform Trolleys

Platform Trolleys Powered Trolleys

Powered Trolleys Shelf & Tiered Trolleys

Shelf & Tiered Trolleys Shopping Trolleys

Shopping Trolleys Stainless Steel Trolleys

Stainless Steel Trolleys Tool Trolleys

Tool Trolleys Utility & Service Carts

Utility & Service Carts Lifting & Handling Equipment

Lifting & Handling Equipment Forklift Attachments

Forklift Attachments Jib Attachments

Jib Attachments Lifting Hoists & Pallet Hooks

Lifting Hoists & Pallet Hooks Load Skates & Tow Tugs

Load Skates & Tow Tugs Manual Stackers & Lifters

Manual Stackers & Lifters Pallet Jacks

Pallet Jacks Pallet Lifters

Pallet Lifters Pallet Rotators & Dispenser

Pallet Rotators & Dispenser Powered Pallet Trucks & Electric Lifters

Powered Pallet Trucks & Electric Lifters Scissor Lift Trolleys and Tables

Scissor Lift Trolleys and Tables Conveyor Equipment

Conveyor Equipment Conveyor Frames & Stands

Conveyor Frames & Stands Roller & Skate Conveyors

Roller & Skate Conveyors Ladders & Access Equipment

Ladders & Access Equipment Container & Yard Ramps

Container & Yard Ramps Ladders & Step Stools

Ladders & Step Stools Work Platforms & Crane Cages

Work Platforms & Crane Cages Drum Handling Equipment

Drum Handling Equipment Drum Storage & Bunding

Drum Storage & Bunding Drum Trolleys & Lifters

Drum Trolleys & Lifters Forklift Drum Handling

Forklift Drum Handling Waste Handling & Bins

Waste Handling & Bins Bin Lifters & Tippers

Bin Lifters & Tippers Plastic Waste & Wheelie Bins

Plastic Waste & Wheelie Bins Steel Waste & Tipping Bins

Steel Waste & Tipping Bins Waste Carts

Waste Carts Dangerous Goods Storage & Spillage

Dangerous Goods Storage & Spillage Aerosol Cans Storage Cages

Aerosol Cans Storage Cages Bunded Pallets & Storage

Bunded Pallets & Storage Corrosive Goods Storage Cabinets

Corrosive Goods Storage Cabinets DG Storage & Trolleys

DG Storage & Trolleys Flammable Liquid Cabinets

Flammable Liquid Cabinets Forklift Gas Storage Cages

Forklift Gas Storage Cages Gas Cylinder Storage Bays

Gas Cylinder Storage Bays Site Storage

Site Storage Spill Kits

Spill Kits Shelving & Storage Equipment

Shelving & Storage Equipment Stillage & Transport Cages

Stillage & Transport Cages 750 Series Cage Configurations

750 Series Cage Configurations Heavy Duty Cabinets

Heavy Duty Cabinets Heavy Duty Shelving

Heavy Duty Shelving Mega Bins & Pallets

Mega Bins & Pallets Packing & Workbenches

Packing & Workbenches Parts Trays & Stor-Pak Bins

Parts Trays & Stor-Pak Bins Pegboard & Louvre Panels

Pegboard & Louvre Panels Plastic Bins & Crates

Plastic Bins & Crates Plastic Handling Solutions Bins

Plastic Handling Solutions Bins Plastic Pallets

Plastic Pallets Stack & Nest Bins

Stack & Nest Bins Pallet Racking Accessories

Pallet Racking Accessories Workplace Equipment

Workplace Equipment Modular Workbenches

Modular Workbenches Electric Height-Adjustable Workbenches

Electric Height-Adjustable Workbenches Floor Matting

Floor Matting General Workplace Equipment

General Workplace Equipment Industrial Weighing Scales

Industrial Weighing Scales Packaging Machinery

Packaging Machinery Stationery Cupboards

Stationery Cupboards Storage and Stillage Cages

Storage and Stillage Cages Tool Trolleys

Tool Trolleys Tooling Cabinets

Tooling Cabinets Workshop Fans and Coolers

Workshop Fans and Coolers Safety Barriers, PPE & Signage

Safety Barriers, PPE & Signage Modular Safety Fence System

Modular Safety Fence System Barriers & Bollards

Barriers & Bollards First Aid Equipment

First Aid Equipment Gloves, Knives and PPE

Gloves, Knives and PPE Signage

Signage Cleaning & Site Supplies

Cleaning & Site Supplies Cleaning Equipment

Cleaning Equipment Cleaning Trolleys

Cleaning Trolleys Rubbish Bins

Rubbish Bins Signs & Traffic Supplies

Signs & Traffic Supplies Construction Equipment

Construction Equipment Construction Trolleys

Construction Trolleys Waste Handling

Waste Handling General Site Equipment

General Site Equipment Concrete Equipment

Concrete Equipment Site Storage

Site Storage Lifting Equipment

Lifting Equipment Verdex Specials

Verdex Specials