Forklift Incidents Are Rising in Australia — Here’s How Workplaces Can Respond

Date Posted:14 October 2025

Forklift incidents continue to rise across Australia, highlighting the ongoing need for stronger safety practices. Explore what the latest data reveals and how workplaces can take practical steps to prevent accidents through better training and equipment.

Verdex Insights: At a Glance

-

The Challenge: Forklift-related incidents remain one of Australia’s leading causes of workplace injuries and fatalities. Despite better technology and awareness, unsafe site layouts, poor traffic control, and limited operator training continue to drive preventable accidents.

-

The Insight: National safety data shows thousands of serious claims each year involving forklifts, with long recovery times and high costs. Effective risk control relies on clear traffic separation, ongoing training, and using quality safety and handling equipment.

-

The Verdex Solution: Verdex helps Australian businesses reduce forklift risks with durable safety barriers, bollards, signage, PPE, and lifting equipment designed for warehousing, logistics, and manufacturing. Our products support compliance, improve site organisation, and create safer, more efficient workplaces.

Forklift Incidents Are Rising in Australia — Here’s How Workplaces Can Respond

Forklifts are vital to Australia’s warehousing, logistics, and manufacturing industries — yet they remain one of the leading causes of serious workplace injuries.

Despite improvements in technology and awareness, recent statistics show forklift safety continues to demand attention.

In a recent LinkedIn post, NSW Minister for Industrial Relations and Work Health and Safety, Sophie Cotsis MP, highlighted that since January 2024, more than 600 forklift incidents have been reported to SafeWork NSW, including four fatalities.

She announced a month-long compliance blitz in October, with more than 250 inspectors conducting unannounced forklift safety checks across NSW.

As Sophie Cotsis MP noted, “Every worker has the right to go to work and return home safely to their loved ones.”

The Ongoing Forklift Safety Challenge

According to Safe Work Australia’s 2023 data, there were 200 workplace fatalities nationwide and over 139,000 serious injury claims.

The transport, postal, and warehousing sector continues to record some of the highest fatality rates of any industry — with forklifts among the most common equipment involved.

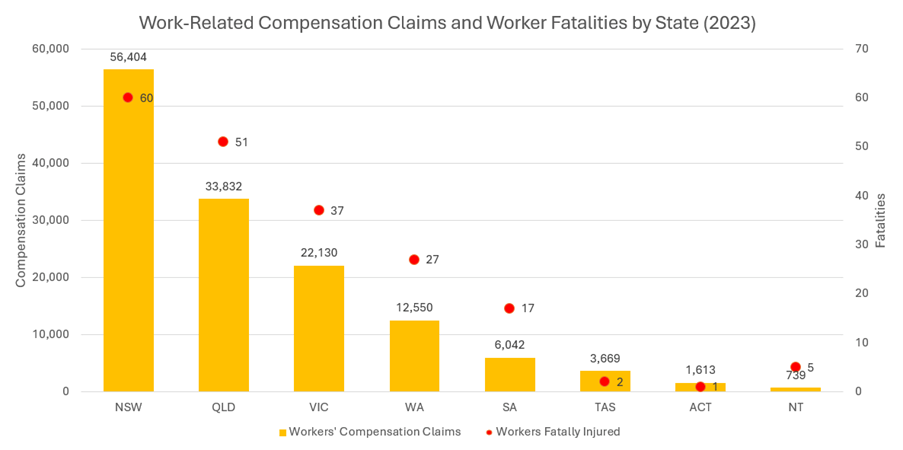

To better understand where and how these injuries occur, Safe Work Australia’s Workers’ Compensation and Fatalities Dashboards provide valuable insight into the scale and impact of workplace harm across each state and territory.

The data by state below shows just how widespread serious injuries and fatalities remain:

| StateState | AuthorityAuthority | Workers' Compensation Claims – 2023Claims ’23 | Median Time Lost (working weeks) – 2022Time Lost ’22 | Median Compensation Paid – 2022Comp Paid ’22 | Workers Fatally Injured – 2023Fatalities ’23 |

|---|---|---|---|---|---|

| - | Safe Work Australia | 139,002 | 7.2 | $14,416 | 200 |

| NSW | SafeWork NSW | 56,404 | 4.2 | $10,574 | 60 |

| QLD | WorkSafe Queensland | 33,832 | 6.4 | $11,332 | 51 |

| VIC | WorkSafe Victoria | 22,130 | 21.2 | $26,351 | 37 |

| WA | WorkSafe Western Australia | 12,550 | 10.8 | $27,858 | 27 |

| SA | SafeWork SA | 6,042 | 8.2 | $18,494 | 17 |

| TAS | WorkSafe Tasmania | 3,669 | 4.9 | $10,361 | 2 |

| ACT | WorkSafe ACT | 1,613 | 7.2 | $19,676 | 1 |

| NT | NT WorkSafe | 739 | 6.0 | $14,021 | 5 |

Swipe sideways to view all columns

Source: Safe Work Australia – Work-related Fatalities Interactive Dashboard and Workers’ Compensation Interactive Dashboard (accessed October 2025).

This data highlights the human and financial impact of preventable incidents, with several key findings standing out:

-

In 2023, Australia recorded 139,002 serious workers’ compensation claims, with a median of 7.2 working weeks lost and an average payout of $14,416 per claim.

-

New South Wales reported the highest number of claims (56,404), while Victoria and Western Australia recorded the longest recovery times and highest average compensation costs, suggesting more severe injuries.

-

Forklift-related and manual handling incidents remain a key driver of serious claims in warehousing and manufacturing.

While machinery design has improved, the underlying causes often remain the same — poor traffic separation, insufficient operator training, and complacency in hazard control.

Why Forklift Incidents Keep Happening and How To Prevent Them

Even with better awareness and equipment standards, many forklift-related incidents continue to stem from simple, preventable issues.

Most occur due to poor traffic management, inadequate training, and unsafe site layouts — all of which can be addressed with proactive safety measures and the right equipment.

The table below outlines some of the most common causes of forklift incidents in Australian workplaces, along with practical ways to reduce these risks.

| Common Problem Problem | Why This Is An Issue Why | How To Prevent Them Solution |

|---|---|---|

| Unclear traffic management | Forklifts and pedestrians share the same space | Install safety barriers, bollards, and clearly marked walkways to separate traffic zones and prevent collisions |

| Expired or inadequate operator training | Unsafe manoeuvres or poor awareness of load limits | Conduct regular training and licence renewals to ensure all forklift operators meet WHS competency standards |

| Overloading or unstable pallets | Loads that shift or tip during movement | Use quality pallets, secure loads properly, and avoid exceeding the forklift’s rated capacity |

| Blocked sightlines or poor lighting | Reduced visibility increases crash risk | Maintain clear visibility through good lighting, mirrors, and unobstructed pathways |

| Cluttered aisles and narrow turning areas | Limited space for safe operation | Keep aisles clean, wide, and organised, with storage solutions that optimise space and reduce congestion |

At Verdex, we’ve seen the difference these measures make. Our range of safety equipment include:

-

safety barriers and bollards for traffic and pedestrian separation

-

PPE clothing and gear to protect workers on the floor

-

workplace signage for clear communication and hazard awareness

-

lifting equipment to reduce manual handling risks

-

And much more designed to support compliance and safety across every site

From Awareness to Action

National Safe Work Month’s 2025 theme — “Safety: Every Job, Every Day” — reminds us that safety isn’t a once-a-year discussion. The latest forklift data proves why ongoing vigilance is essential.

Every forklift movement carries risk, but with the right equipment, planning, and culture, those risks can be controlled.

Verdex supports Australian workplaces with compliant, durable solutions that keep people safe — every job, every day.

Explore our full range of safety and materials-handling products today or read more about National Safe Work Month 2025.

Trolleys & Hand Trucks

Trolleys & Hand Trucks Cage Trolleys

Cage Trolleys Cleaning Carts & Trolleys

Cleaning Carts & Trolleys Construction Trolleys

Construction Trolleys Custom Trolleys

Custom Trolleys Hand Trucks & Dollies

Hand Trucks & Dollies Laundry/Linen Trolleys

Laundry/Linen Trolleys Lifting Trolleys

Lifting Trolleys Order Picking Trolleys

Order Picking Trolleys Panel Cart Trolleys

Panel Cart Trolleys Platform Trolleys

Platform Trolleys Powered Trolleys

Powered Trolleys Shelf & Tiered Trolleys

Shelf & Tiered Trolleys Shopping Trolleys

Shopping Trolleys Stainless Steel Trolleys

Stainless Steel Trolleys Tool Trolleys

Tool Trolleys Utility & Service Carts

Utility & Service Carts Lifting & Handling Equipment

Lifting & Handling Equipment Forklift Attachments

Forklift Attachments Jib Attachments

Jib Attachments Lifting Hoists & Pallet Hooks

Lifting Hoists & Pallet Hooks Load Skates & Tow Tugs

Load Skates & Tow Tugs Manual Stackers & Lifters

Manual Stackers & Lifters Pallet Jacks

Pallet Jacks Pallet Lifters

Pallet Lifters Pallet Rotators & Dispenser

Pallet Rotators & Dispenser Powered Pallet Trucks & Electric Lifters

Powered Pallet Trucks & Electric Lifters Scissor Lift Trolleys and Tables

Scissor Lift Trolleys and Tables Conveyor Equipment

Conveyor Equipment Conveyor Frames & Stands

Conveyor Frames & Stands Roller & Skate Conveyors

Roller & Skate Conveyors Ladders & Access Equipment

Ladders & Access Equipment Container & Yard Ramps

Container & Yard Ramps Ladders & Step Stools

Ladders & Step Stools Work Platforms & Crane Cages

Work Platforms & Crane Cages Drum Handling Equipment

Drum Handling Equipment Drum Storage & Bunding

Drum Storage & Bunding Drum Trolleys & Lifters

Drum Trolleys & Lifters Forklift Drum Handling

Forklift Drum Handling Waste Handling & Bins

Waste Handling & Bins Bin Lifters & Tippers

Bin Lifters & Tippers Plastic Waste & Wheelie Bins

Plastic Waste & Wheelie Bins Steel Waste & Tipping Bins

Steel Waste & Tipping Bins Waste Carts

Waste Carts Dangerous Goods Storage & Spillage

Dangerous Goods Storage & Spillage Aerosol Cans Storage Cages

Aerosol Cans Storage Cages Bunded Pallets & Storage

Bunded Pallets & Storage Corrosive Goods Storage Cabinets

Corrosive Goods Storage Cabinets DG Storage & Trolleys

DG Storage & Trolleys Flammable Liquid Cabinets

Flammable Liquid Cabinets Forklift Gas Storage Cages

Forklift Gas Storage Cages Gas Cylinder Storage Bays

Gas Cylinder Storage Bays Site Storage

Site Storage Spill Kits

Spill Kits Shelving & Storage Equipment

Shelving & Storage Equipment Stillage & Transport Cages

Stillage & Transport Cages 750 Series Cage Configurations

750 Series Cage Configurations Heavy Duty Cabinets

Heavy Duty Cabinets Heavy Duty Shelving

Heavy Duty Shelving Mega Bins & Pallets

Mega Bins & Pallets Packing & Workbenches

Packing & Workbenches Parts Trays & Stor-Pak Bins

Parts Trays & Stor-Pak Bins Pegboard & Louvre Panels

Pegboard & Louvre Panels Plastic Bins & Crates

Plastic Bins & Crates Plastic Handling Solutions Bins

Plastic Handling Solutions Bins Plastic Pallets

Plastic Pallets Stack & Nest Bins

Stack & Nest Bins Pallet Racking Accessories

Pallet Racking Accessories Workplace Equipment

Workplace Equipment Modular Workbenches

Modular Workbenches Electric Height-Adjustable Workbenches

Electric Height-Adjustable Workbenches Floor Matting

Floor Matting General Workplace Equipment

General Workplace Equipment Industrial Weighing Scales

Industrial Weighing Scales Packaging Machinery

Packaging Machinery Stationery Cupboards

Stationery Cupboards Storage and Stillage Cages

Storage and Stillage Cages Tool Trolleys

Tool Trolleys Tooling Cabinets

Tooling Cabinets Workshop Fans and Coolers

Workshop Fans and Coolers Safety Barriers, PPE & Signage

Safety Barriers, PPE & Signage Modular Safety Fence System

Modular Safety Fence System Barriers & Bollards

Barriers & Bollards First Aid Equipment

First Aid Equipment Gloves, Knives and PPE

Gloves, Knives and PPE Signage

Signage Cleaning & Site Supplies

Cleaning & Site Supplies Cleaning Equipment

Cleaning Equipment Cleaning Trolleys

Cleaning Trolleys Rubbish Bins

Rubbish Bins Signs & Traffic Supplies

Signs & Traffic Supplies Construction Equipment

Construction Equipment Construction Trolleys

Construction Trolleys Waste Handling

Waste Handling General Site Equipment

General Site Equipment Concrete Equipment

Concrete Equipment Site Storage

Site Storage Lifting Equipment

Lifting Equipment Verdex Specials

Verdex Specials