Best Practices for First Aid Kits in Warehouses

Date Posted:16 October 2025

Don’t risk being unprepared. Learn best practices for first aid kits in warehouses to protect workers and comply with safety regulations.

Verdex Insights: At a Glance

-

The Challenge: Warehouse environments face a higher risk of injury due to heavy machinery, manual handling, and fast-paced operations. Emergency preparedness is essential for WHS compliance and worker safety.

-

The Insight: A well-stocked, clearly located first aid kit is critical for fast response and compliance. Industrial-grade kits designed for warehouse conditions help prevent minor injuries from becoming major incidents.

-

The Verdex Solution: Verdex supplies WHS-compliant first aid kits and safety gear purpose-built for warehousing, logistics, and manufacturing. Our durable, industrial-grade products help businesses stay prepared, protect staff, and maintain safe, compliant workplaces.

Why First Aid Kits Are Critical in Warehouse Environments

Warehouses are dynamic and often hazardous workplaces. With heavy machinery, forklifts, shelving systems, and manual handling activities, the risk of injury is significantly higher than in office-based settings. Common incidents include cuts, crush injuries, sprains, and even chemical exposure.

In these fast-paced environments, immediate access to a well-stocked first aid kit can be the difference between a minor injury and a serious medical emergency. A prompt response also limits downtime and ensures compliance with Workplace Health and Safety (WHS) regulations, which mandate that first aid equipment must be accessible, suitable for the risks, and clearly signed.

Beyond legal obligations, having visible and well-maintained first aid kits helps build a culture of safety. It shows that you value your workers' wellbeing, something that can positively impact morale and productivity across your team.

Common Workplace Injuries in Warehouses

Warehouses present a wide range of potential injury types due to the varied tasks performed within them. Here are some of the most common:

-

Cuts and abrasions: Often caused by sharp packaging tools, broken pallets, or unguarded edges on shelving or machinery.

-

Sprains and strains: Frequently occur when lifting, stacking, or moving heavy loads incorrectly or without mechanical aid.

-

Forklift-related injuries: These include crush injuries, foot impacts, and collisions—especially in shared pedestrian/forklift areas. Installing safety barriers and security bollards alongside first aid kits helps reduce these risks significantly.

-

Eye injuries: Dust, wood splinters, or chemical splashes can cause eye irritation or damage, particularly in unpacking or processing zones.

-

Slips, trips, and falls: Resulting from wet surfaces, misplaced tools, or uneven flooring—especially near loading docks or entryways.

-

Burns or chemical exposure: In warehouses handling flammable goods, industrial cleaners, or batteries, chemical burns can be a serious concern.

Having the right first aid resources readily available is key to managing these types of incidents effectively.

What Should Be in a Warehouse First Aid Kit?

A warehouse first aid kit should include general first aid supplies along with items that address the specific risks of an industrial environment.

Basic Items

-

Adhesive bandages (Band-Aids)

-

Sterile wound dressings

-

Antiseptic wipes

-

Non-stick pads

-

Disposable gloves

-

Tape and scissors

Gloves and other PPE clothing and safety gear should always complement your first aid kit to keep responders safe during treatment.

Industrial-Specific Supplies

-

Burn gel and burn dressings

-

Saline solution for wound or eye irrigation

-

Trauma dressings for heavy bleeding

-

Eye wash bottles and pods

-

Snake bite bandages (particularly in regional or outdoor warehouses)

Emergency Equipment

-

CPR mask or resuscitation face shield

-

Emergency thermal blanket

-

First aid manual or step-by-step guide

These kits should be tailored to the size and activity of the warehouse, and replenished regularly to remain effective. As a trusted partner, Verdex supports warehouses nationwide with compliant safety gear and expert advice.

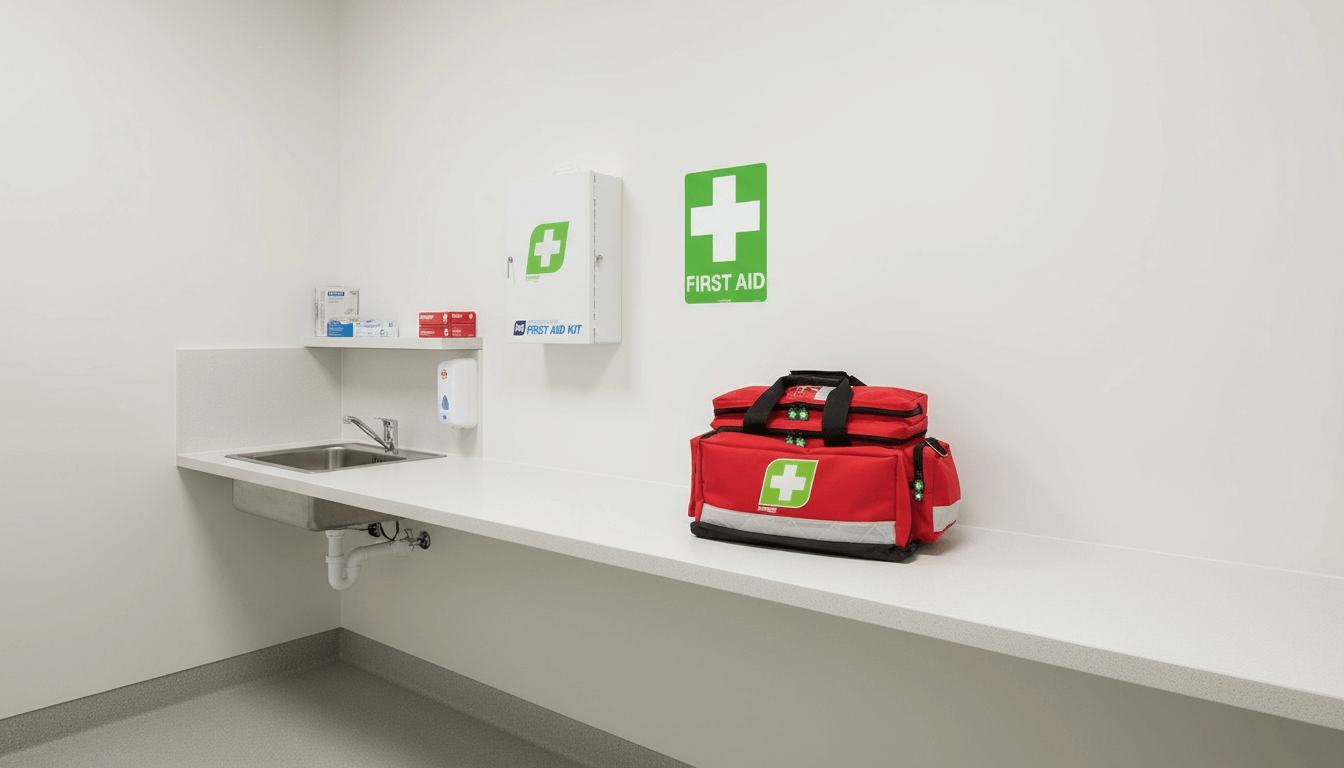

Where to Locate First Aid Kits in a Warehouse

Proper placement of first aid kits is just as important as their contents. WHS guidelines stress that kits must be clearly visible, unobstructed, and signed with appropriate first aid signage. Pairing kits with workplace safety signage ensures they can be found quickly in an emergency.

Strategic locations include:

-

Loading bays – where manual handling and forklift activity are highest

-

Administrative or office areas – for easy access by supervisors or first aid officers

-

Lunchrooms or break areas – where minor kitchen accidents may occur

-

Designated first aid rooms – for larger facilities that require dedicated treatment spaces

Additionally, portable kits can be mounted on forklifts or carried by mobile staff working across large or multiple warehouse zones.

Clear signage and unobstructed access are crucial during emergencies, when every second counts.

Why You Should Choose Industrial-Grade First Aid Kits

Unlike standard retail kits, industrial-grade first aid kits are purpose-built to suit demanding workplaces like warehouses.

Here’s why they’re essential:

-

Built for durability – Often enclosed in metal or heavy-duty plastic cases that withstand dusty, wet, or rugged environments.

-

Comprehensive contents – Covering more than just cuts and bruises, they include trauma supplies, burn care, and CPR equipment.

-

WHS-compliant – Industrial kits meet or exceed Safe Work Australia’s First Aid in the Workplace Code of Practice.

At Verdex, we offer warehouse-specific kits that are pre-packed, compliant, and available in various configurations—from wall-mounted cabinets to portable kits for mobile teams. We also provide restocking supplies and customised solutions tailored to your specific layout and risks.

Extra Items to Consider

In addition to your first aid kits, the following equipment can greatly improve warehouse emergency preparedness:

-

AED (Automated External Defibrillator) – Life-saving in cardiac emergencies, especially in large facilities.

-

Eyewash stations – For fast response to dust or chemical exposure.

-

Extra PPE – Such as face masks, gloves, and spill containment gear.

These items provide added layers of safety and may be required under your site’s WHS risk assessment.

Keep Your Warehouse Prepared with First Aid Kits

Verdex offers first aid kits specifically designed for warehouse and industrial environments across Australia. We understand the hazards you face daily—whether it’s forklift traffic, chemical exposure, or manual handling injuries.

Our kits are:

-

Built tough for Australian workplaces

-

Fully compliant with WHS guidelines

-

Available in various sizes and formats

-

Easy to install and restock

Get in touch with the Verdex team today to discuss your site’s needs or arrange a quote. We also supply a full range of safety gear, including bollards, spill control, PPE, signage, and more to help you maintain a safe, compliant facility.

Get in Touch with Verdex

At Verdex, we provide first aid kits and safety solutions designed specifically for warehouse and industrial environments. Our team can help you choose the right kit for your site and keep your workplace compliant.

-

Email us at sales@verdex.com.au

-

Fill out our online contact form

Trolleys & Hand Trucks

Trolleys & Hand Trucks Cage Trolleys

Cage Trolleys Cleaning Carts & Trolleys

Cleaning Carts & Trolleys Construction Trolleys

Construction Trolleys Custom Trolleys

Custom Trolleys Hand Trucks & Dollies

Hand Trucks & Dollies Laundry/Linen Trolleys

Laundry/Linen Trolleys Lifting Trolleys

Lifting Trolleys Order Picking Trolleys

Order Picking Trolleys Panel Cart Trolleys

Panel Cart Trolleys Platform Trolleys

Platform Trolleys Powered Trolleys

Powered Trolleys Shelf & Tiered Trolleys

Shelf & Tiered Trolleys Shopping Trolleys

Shopping Trolleys Stainless Steel Trolleys

Stainless Steel Trolleys Tool Trolleys

Tool Trolleys Utility & Service Carts

Utility & Service Carts Lifting & Handling Equipment

Lifting & Handling Equipment Forklift Attachments

Forklift Attachments Jib Attachments

Jib Attachments Lifting Hoists & Pallet Hooks

Lifting Hoists & Pallet Hooks Load Skates & Tow Tugs

Load Skates & Tow Tugs Manual Stackers & Lifters

Manual Stackers & Lifters Pallet Jacks

Pallet Jacks Pallet Lifters

Pallet Lifters Pallet Rotators & Dispenser

Pallet Rotators & Dispenser Powered Pallet Trucks & Electric Lifters

Powered Pallet Trucks & Electric Lifters Scissor Lift Trolleys and Tables

Scissor Lift Trolleys and Tables Conveyor Equipment

Conveyor Equipment Conveyor Frames & Stands

Conveyor Frames & Stands Roller & Skate Conveyors

Roller & Skate Conveyors Ladders & Access Equipment

Ladders & Access Equipment Container & Yard Ramps

Container & Yard Ramps Ladders & Step Stools

Ladders & Step Stools Work Platforms & Crane Cages

Work Platforms & Crane Cages Drum Handling Equipment

Drum Handling Equipment Drum Storage & Bunding

Drum Storage & Bunding Drum Trolleys & Lifters

Drum Trolleys & Lifters Forklift Drum Handling

Forklift Drum Handling Waste Handling & Bins

Waste Handling & Bins Bin Lifters & Tippers

Bin Lifters & Tippers Plastic Waste & Wheelie Bins

Plastic Waste & Wheelie Bins Steel Waste & Tipping Bins

Steel Waste & Tipping Bins Waste Carts

Waste Carts Dangerous Goods Storage & Spillage

Dangerous Goods Storage & Spillage Aerosol Cans Storage Cages

Aerosol Cans Storage Cages Bunded Pallets & Storage

Bunded Pallets & Storage Corrosive Goods Storage Cabinets

Corrosive Goods Storage Cabinets DG Storage & Trolleys

DG Storage & Trolleys Flammable Liquid Cabinets

Flammable Liquid Cabinets Forklift Gas Storage Cages

Forklift Gas Storage Cages Gas Cylinder Storage Bays

Gas Cylinder Storage Bays Site Storage

Site Storage Spill Kits

Spill Kits Shelving & Storage Equipment

Shelving & Storage Equipment Stillage & Transport Cages

Stillage & Transport Cages 750 Series Cage Configurations

750 Series Cage Configurations Heavy Duty Cabinets

Heavy Duty Cabinets Heavy Duty Shelving

Heavy Duty Shelving Mega Bins & Pallets

Mega Bins & Pallets Packing & Workbenches

Packing & Workbenches Parts Trays & Stor-Pak Bins

Parts Trays & Stor-Pak Bins Pegboard & Louvre Panels

Pegboard & Louvre Panels Plastic Bins & Crates

Plastic Bins & Crates Plastic Handling Solutions Bins

Plastic Handling Solutions Bins Plastic Pallets

Plastic Pallets Stack & Nest Bins

Stack & Nest Bins Pallet Racking Accessories

Pallet Racking Accessories Workplace Equipment

Workplace Equipment Modular Workbenches

Modular Workbenches Electric Height-Adjustable Workbenches

Electric Height-Adjustable Workbenches Floor Matting

Floor Matting General Workplace Equipment

General Workplace Equipment Industrial Weighing Scales

Industrial Weighing Scales Packaging Machinery

Packaging Machinery Stationery Cupboards

Stationery Cupboards Storage and Stillage Cages

Storage and Stillage Cages Tool Trolleys

Tool Trolleys Tooling Cabinets

Tooling Cabinets Workshop Fans and Coolers

Workshop Fans and Coolers Safety Barriers, PPE & Signage

Safety Barriers, PPE & Signage Modular Safety Fence System

Modular Safety Fence System Barriers & Bollards

Barriers & Bollards First Aid Equipment

First Aid Equipment Gloves, Knives and PPE

Gloves, Knives and PPE Signage

Signage Cleaning & Site Supplies

Cleaning & Site Supplies Cleaning Equipment

Cleaning Equipment Cleaning Trolleys

Cleaning Trolleys Rubbish Bins

Rubbish Bins Signs & Traffic Supplies

Signs & Traffic Supplies Construction Equipment

Construction Equipment Construction Trolleys

Construction Trolleys Waste Handling

Waste Handling General Site Equipment

General Site Equipment Concrete Equipment

Concrete Equipment Site Storage

Site Storage Lifting Equipment

Lifting Equipment Verdex Specials

Verdex Specials