How to Handle Heavy Pallet Loads Safely and Avoid Damage or Injury

Date Posted:8 December 2025

Heavy pallet handling remains a major cause of strain injuries and stock damage. Learn how to reduce risks with better processes with some simple safe practices and the right types of lifting equipment improving efficiency.

Verdex Insights: At a Glance

-

The Challenge: Heavy pallet handling remains one of the most common causes of injuries and product damage in Australian warehouses, factories, and logistics operations. Many workplaces still rely on outdated manual lifting methods or under-rated equipment, leading to strains, crush injuries, broken pallets, damaged stock, rising insurance costs, and WHS compliance risks.

-

The Insight: Most pallet-related incidents are preventable. Small errors like lifting by hand, using damaged pallets, overloading, or skipping equipment checks quickly compound into injury risks and workflow delays. Introducing the right handling tools, better pallet processes, and consistent training can significantly reduce strain, protect goods, and improve daily productivity.

-

The Verdex Solution: Verdex supplies a complete range of WHS-compliant pallet handling and lifting equipment designed for Australian workplaces. Our solutions help eliminate manual handling risks while improving efficiency and reducing product damage. With durable construction, fast nationwide delivery, expert advice, and a Price Beat Guarantee, Verdex supports safer, faster, and more compliant pallet handling across warehouses, logistics centres, and manufacturing environments.

How to Handle Heavy Pallet Loads Safely and Avoid Damage or Injury

Manual pallet handling is still common in many Australian warehouses, factories, and logistics operations. Whether you are running a large distribution centre or a smaller local business, chances are your team moves, lifts, or stacks heavy pallet loads every day.

Unfortunately, this routine task is also one of the most frequent causes of workplace injuries and product damage. Workers often rely on outdated manual methods or under-rated equipment, putting both themselves and your goods at risk.

The results can be serious: strains, crush injuries, broken pallets, and damaged stock. Beyond the immediate impact, unsafe pallet handling increases downtime, insurance costs, and the risk of breaching Work Health and Safety (WHS) requirements.

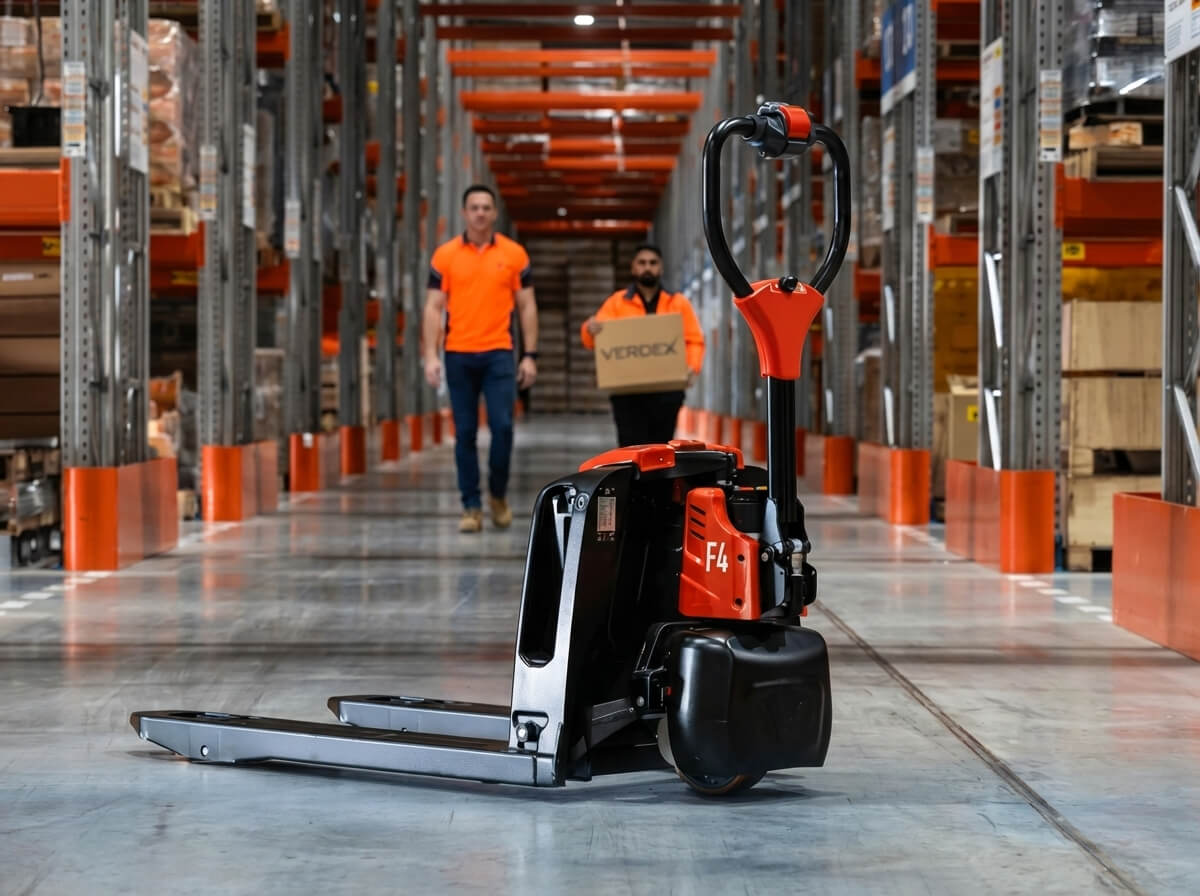

With the right approach, however, it is entirely possible to handle heavy pallet loads safely, efficiently, and in full compliance with Australian safety standards. Equipment such as our Verdex Electric Pallet Truck 1.5 Tonne helps make this process faster, safer, and more consistent.

Why Safe Pallet Handling Matters in Australian Workplaces

Safe pallet handling is not just about avoiding injuries. It also protects your business reputation, improves productivity, and prevents unnecessary loss of goods.

Every year, Australian workers experience thousands of manual handling injuries, many related to lifting or moving heavy items like pallets. According to Safe Work Australia, poor manual handling remains a major cause of workplace injuries, particularly in the transport, warehousing, and manufacturing sectors.

When pallets are handled correctly using appropriate lifting equipment, the risk of strain, crush injuries, and product damage decreases significantly. Safe handling also reduces fatigue, which in turn keeps workers more alert and efficient throughout their shifts.

The Hidden Risks of Manual Pallet Handling and Heavy Loads

Manual pallet handling might look simple, but the risks are often underestimated. Even experienced operators can develop bad habits that increase strain or create unsafe conditions.

Physical Injury Risks

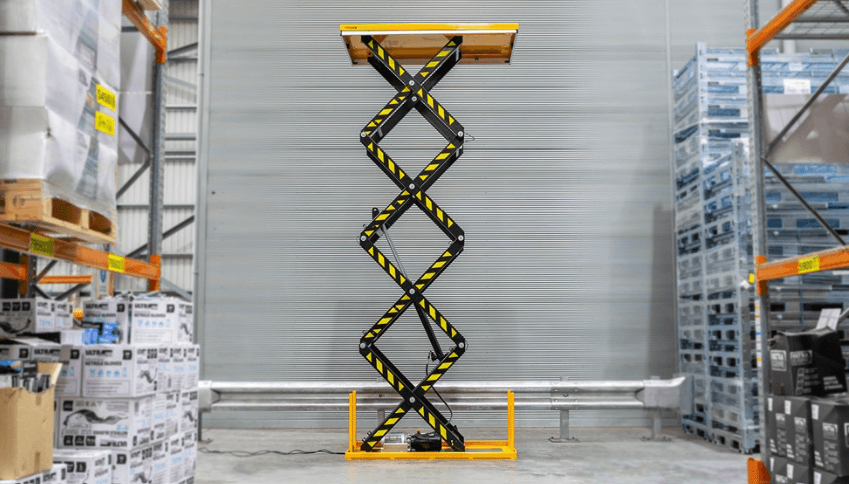

Without mechanical assistance, lifting or moving a heavy pallet can easily exceed safe weight limits. Common injuries include lower back strains, shoulder and knee injuries, and crushed fingers or toes from falling pallets. Mechanical lifting aids (such as our Single Scissor Electric Lift Table) help keep loads at a safe working height, reducing bending, overreaching, and the risk of sudden strain injuries.

Product Damage and Waste

Improper stacking, rough handling, or using damaged pallets can cause goods to shift or collapse during movement. This can result in product loss, returns, and downtime for clean-up and re-packing.

Compliance and Legal Liabilities

Unsafe manual handling practices can lead to WHS breaches. Employers have a legal duty under Australian law to eliminate or reduce manual handling risks as far as reasonably practicable. Failing to do so can result in penalties or legal claims.

Common Pallet Handling Mistakes That Lead to Damage or Injury

Many of the most frequent pallet handling problems come from small but repeated errors in daily tasks. Identifying and correcting these can greatly improve safety.

-

Lifting pallets by hand instead of using a jack or lifting table.

-

Overloading pallets beyond their rated weight capacity.

-

Stacking pallets unevenly, causing them to lean or collapse.

-

Using damaged pallets, with cracked boards or broken corners.

-

Moving loads without checking clearance around doorways or aisles.

-

Failing to secure loads with straps or shrink wrap before transport.

When these mistakes occur repeatedly, they lead to both short-term injuries and long-term equipment damage.

If you want to understand the broader impact of manual lifting on productivity and safety, see our blog about How Manual Lifting Hurts Your Business and 7 Ways Lifting Equipment Can Reduce It.

6 Safe Practices for Handling Heavy Pallet Loads

Handling pallets safely involves a combination of correct technique, the right equipment, and consistent training.

1. Assess the Load Before Moving It

Always check the weight, stability, and packaging of a pallet before attempting to move it. Ensure the load is evenly distributed and secured.

2. Use Proper Lifting Techniques

When manual handling is unavoidable, workers should bend at the knees, not the waist, and keep the load close to the body. Twisting while lifting should be avoided at all times.

3. Plan Your Route

Before moving a pallet, make sure the pathway is clear of obstructions and spills. Plan where the pallet will be placed to avoid unnecessary double-handling.

4. Stack Pallets Safely

Stack pallets evenly, with heavier items at the bottom. Avoid stacking too high or using damaged pallets that cannot bear the load.

5. Inspect Equipment Regularly

Check pallet jacks, trolleys, and pallet lift tables before each use to ensure they are in good working order. Faulty equipment should be tagged out immediately.

6. Train Your Staff

Training is essential to maintaining safety. Make sure workers understand both the correct handling techniques and how to operate lifting equipment safely.

Types of Lifting and Handling Equipment Helping to Improve Pallet Safety and Efficiency

The most effective way to eliminate manual handling risks is to use appropriate lifting and transport equipment. Modern material handling tools not only make the job safer but also increase productivity and reduce fatigue.

Pallet Jacks

Pallet jacks are essential in any warehouse or storage environment. They allow workers to move heavy loads smoothly without physical strain. Both manual and electric pallet jacks are available, depending on the scale of your operations.

Scissor Lift Tables

These provide adjustable height platforms that reduce the need for bending or reaching when stacking or unpacking pallets. By keeping the load at an optimal working height, scissor lift tables help prevent back injuries and make loading faster.

Stillage Cages and Pallet Cages

Stillages offer a secure way to transport irregular or fragile goods that might otherwise fall or be damaged on open pallets. Many are collapsible, making them convenient for storage when not in use.

Platform Trolleys

Ideal for smaller or lighter pallet loads, platform trolleys make it easier to manoeuvre materials across the warehouse floor. They improve efficiency by reducing the number of trips required for each task.

Safety Barriers and Guard Rails

Physical barriers and bollards around pallet loading zones protect workers and prevent collisions between forklifts, trolleys, and pedestrians. These barriers help maintain clear, safe pathways during busy operations.

By combining these tools, warehouses can drastically reduce the time and effort needed to move heavy pallet loads while maintaining high safety standards.

Meeting Australian WHS Standards for Manual Handling and Pallet Safety

Safe Work Australia’s guidelines on hazardous manual tasks require employers to identify and control risks associated with lifting, pushing, pulling, or carrying heavy items.

Key steps include:

-

Risk assessment: Identify which tasks involve heavy or awkward loads.

-

Engineering controls: Introduce equipment that eliminates or reduces manual effort.

-

Administrative controls: Rotate staff, limit load weights, and train workers in correct techniques.

-

Regular reviews: Reassess equipment and practices as workloads and operations change.

By providing appropriate handling aids such as pallet jacks, scissor lift tables, or stillage cages, businesses demonstrate compliance while protecting staff health and maintaining operational efficiency.

Protect Your Team and Your Goods with the Right Pallet Handling Equipment

Investing in safe and efficient pallet handling equipment is not just about compliance. It is about protecting your people, your products, and your profits.

Verdex offers a complete range of Australian-compliant lifting and material handling equipment designed for warehouse, logistics, and manufacturing environments. This includes high-performance solutions like the High Lift Scissor Electric Lift Table, which allows operators to position pallet loads at an optimal height for packing, sorting, or unloading—reducing strain, improving workflow, and ensuring safer handling of heavy or awkward goods.

When you choose Verdex, you benefit from:

-

Australian Standards-compliant products that meet strict safety requirements.

-

Fast nationwide delivery to minimise downtime.

-

Price Beat Guarantee to ensure value for money.

-

Expert local advice from professionals who understand warehouse operations.

-

Durable, proven equipment built to handle Australia’s toughest conditions.

Every piece of Verdex equipment is designed to help your team work safer and faster, with less effort and fewer risks.

Trolleys & Hand Trucks

Trolleys & Hand Trucks Cage Trolleys

Cage Trolleys Cleaning Carts & Trolleys

Cleaning Carts & Trolleys Construction Trolleys

Construction Trolleys Custom Trolleys

Custom Trolleys Hand Trucks & Dollies

Hand Trucks & Dollies Laundry/Linen Trolleys

Laundry/Linen Trolleys Lifting Trolleys

Lifting Trolleys Order Picking Trolleys

Order Picking Trolleys Panel Cart Trolleys

Panel Cart Trolleys Platform Trolleys

Platform Trolleys Powered Trolleys

Powered Trolleys Shelf & Tiered Trolleys

Shelf & Tiered Trolleys Shopping Trolleys

Shopping Trolleys Stainless Steel Trolleys

Stainless Steel Trolleys Tool Trolleys

Tool Trolleys Utility & Service Carts

Utility & Service Carts Lifting & Handling Equipment

Lifting & Handling Equipment Forklift Attachments

Forklift Attachments Jib Attachments

Jib Attachments Lifting Hoists & Pallet Hooks

Lifting Hoists & Pallet Hooks Load Skates & Tow Tugs

Load Skates & Tow Tugs Manual Stackers & Lifters

Manual Stackers & Lifters Pallet Jacks

Pallet Jacks Pallet Lifters

Pallet Lifters Pallet Rotators & Dispenser

Pallet Rotators & Dispenser Powered Pallet Trucks & Electric Lifters

Powered Pallet Trucks & Electric Lifters Scissor Lift Trolleys and Tables

Scissor Lift Trolleys and Tables Conveyor Equipment

Conveyor Equipment Conveyor Frames & Stands

Conveyor Frames & Stands Roller & Skate Conveyors

Roller & Skate Conveyors Ladders & Access Equipment

Ladders & Access Equipment Container & Yard Ramps

Container & Yard Ramps Ladders & Step Stools

Ladders & Step Stools Work Platforms & Crane Cages

Work Platforms & Crane Cages Drum Handling Equipment

Drum Handling Equipment Drum Storage & Bunding

Drum Storage & Bunding Drum Trolleys & Lifters

Drum Trolleys & Lifters Forklift Drum Handling

Forklift Drum Handling Waste Handling & Bins

Waste Handling & Bins Bin Lifters & Tippers

Bin Lifters & Tippers Plastic Waste & Wheelie Bins

Plastic Waste & Wheelie Bins Steel Waste & Tipping Bins

Steel Waste & Tipping Bins Waste Carts

Waste Carts Dangerous Goods Storage & Spillage

Dangerous Goods Storage & Spillage Aerosol Cans Storage Cages

Aerosol Cans Storage Cages Bunded Pallets & Storage

Bunded Pallets & Storage Corrosive Goods Storage Cabinets

Corrosive Goods Storage Cabinets DG Storage & Trolleys

DG Storage & Trolleys Flammable Liquid Cabinets

Flammable Liquid Cabinets Forklift Gas Storage Cages

Forklift Gas Storage Cages Gas Cylinder Storage Bays

Gas Cylinder Storage Bays Site Storage

Site Storage Spill Kits

Spill Kits Shelving & Storage Equipment

Shelving & Storage Equipment Stillage & Transport Cages

Stillage & Transport Cages 750 Series Cage Configurations

750 Series Cage Configurations Heavy Duty Cabinets

Heavy Duty Cabinets Heavy Duty Shelving

Heavy Duty Shelving Mega Bins & Pallets

Mega Bins & Pallets Packing & Workbenches

Packing & Workbenches Parts Trays & Stor-Pak Bins

Parts Trays & Stor-Pak Bins Pegboard & Louvre Panels

Pegboard & Louvre Panels Plastic Bins & Crates

Plastic Bins & Crates Plastic Handling Solutions Bins

Plastic Handling Solutions Bins Plastic Pallets

Plastic Pallets Stack & Nest Bins

Stack & Nest Bins Pallet Racking Accessories

Pallet Racking Accessories Workplace Equipment

Workplace Equipment Modular Workbenches

Modular Workbenches Electric Height-Adjustable Workbenches

Electric Height-Adjustable Workbenches Floor Matting

Floor Matting General Workplace Equipment

General Workplace Equipment Industrial Weighing Scales

Industrial Weighing Scales Packaging Machinery

Packaging Machinery Stationery Cupboards

Stationery Cupboards Storage and Stillage Cages

Storage and Stillage Cages Tool Trolleys

Tool Trolleys Tooling Cabinets

Tooling Cabinets Workshop Fans and Coolers

Workshop Fans and Coolers Safety Barriers, PPE & Signage

Safety Barriers, PPE & Signage Modular Safety Fence System

Modular Safety Fence System Barriers & Bollards

Barriers & Bollards First Aid Equipment

First Aid Equipment Gloves, Knives and PPE

Gloves, Knives and PPE Signage

Signage Cleaning & Site Supplies

Cleaning & Site Supplies Cleaning Equipment

Cleaning Equipment Cleaning Trolleys

Cleaning Trolleys Rubbish Bins

Rubbish Bins Signs & Traffic Supplies

Signs & Traffic Supplies Construction Equipment

Construction Equipment Construction Trolleys

Construction Trolleys Waste Handling

Waste Handling General Site Equipment

General Site Equipment Concrete Equipment

Concrete Equipment Site Storage

Site Storage Lifting Equipment

Lifting Equipment Verdex Specials

Verdex Specials