How Verdex is Helping Reduce Workplace Strain and Prevent Hazards in Australia

Date Posted:11 December 2025

Many injuries and hazards happen because workers are forced to compensate for poor equipment or layouts. Learn how Verdex is reshaping workplaces with practical solutions that reduce strain and improve safety across Australia.

Verdex Insights: At a Glance

-

The Challenge: Across Australia, thousands of workers face daily strain from heavy lifting, awkward postures, cluttered walk areas, and unsafe manual handling. These risks contribute to high injury rates, lost productivity, rising insurance costs, and WHS compliance issues, especially in warehouses, factories, and trade environments.

-

The Insight: Most workplace strains and hazards occur because workers are forced to compensate for poor equipment or inefficient layouts. When engineering controls such as lifting aids, trolleys, shelving, and safety barriers are missing, human effort fills the gap. This increases fatigue, slows operations, and elevates accident risk. The fastest way to reduce these injuries is to remove the physical strain at the source through smarter, purpose-built equipment.

-

The Verdex Solution: Verdex helps Australian workplaces reduce strain and prevent hazards by supplying high-quality material handling, safety, and ergonomic equipment designed for real-world conditions. We provide practical tools that improve safety and efficiency. With WHS-compliant products, expert advice, and nationwide delivery, we support safer, more organised, and more productive workplaces across every industry.

How Verdex is Helping Reduce Workplace Strain and Prevent Hazards in Australia

Across Australia, thousands of workers in warehouses, factories, and worksites face the same daily challenge: physically demanding tasks that lead to fatigue, injury, and inefficiency. Despite safety training and policies, manual handling and preventable hazards remain two of the biggest causes of workplace incidents nationwide.

Whether it’s a warehouse operator overexerting while lifting, a tradesperson tripping over cluttered materials, or an employee straining at an awkward workstation, the outcome is the same: lost productivity, increased costs, and avoidable pain.

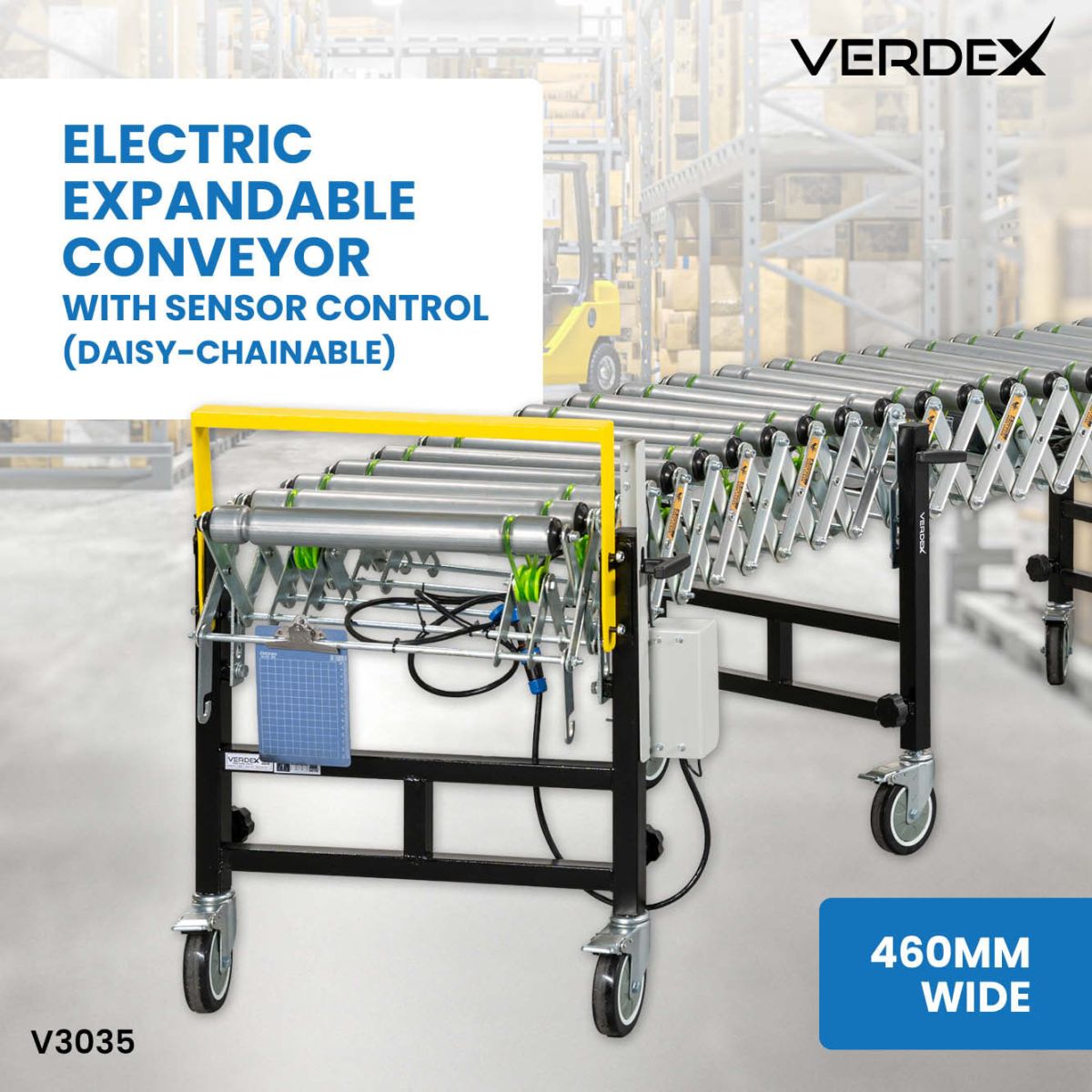

Verdex is helping to change that. By providing smart, well-designed materials handling and workplace equipment, Verdex helps Australian businesses prevent these risks at the source, reducing strain, improving ergonomics, and building safer, more efficient environments. This includes automated solutions such as our Electric Expandable Conveyor with Sensor Control (Daisy-Chainable), which reduces manual handling, speeds up loading tasks, and provides safer product flow across busy work areas.

Electric Expandable Conveyor With Sensor Control next to two warehouse retail specialists ↗

Electric Expandable Conveyor With Sensor Control next to two warehouse retail specialists ↗

V3035: Electric Expandable Conveyor With Sensor Control (Daisy-Chainable) ↗

V3035: Electric Expandable Conveyor With Sensor Control (Daisy-Chainable) ↗

The Ongoing Challenge of Workplace Strain

According to Safe Work Australia, manual handling injuries and slips, trips, and falls consistently rank among the most common causes of workplace incidents. These injuries are not only physically damaging but also financially costly. They contribute to millions of dollars in compensation claims and lost working hours every year.

In many cases, these injuries occur because workers are forced to adapt to unsafe or inefficient environments. They lift too much, twist awkwardly, or navigate through disorganised areas because there’s no better option. Training can reduce some risk, but without the right tools and equipment, workers remain vulnerable.

For workplaces looking to further reduce these risks, our blog on How to Prevent Common Accidents with Material Handling Equipment explores practical steps and equipment strategies that help stop incidents before they occur.

That’s where Verdex steps in, helping Australian businesses redesign their workflows and workplaces around equipment that supports people, rather than pushing them past their limits.

The True Cost of Workplace Strain and Hazards

Workplace strain doesn’t just affect employees; it affects the entire business. Beyond the human cost, the ripple effects can be felt across operations.

-

Lost Productivity: Injured or fatigued workers can’t perform at their full potential. Replacements or reassignments add to disruption.

-

Rising Compensation and Insurance Costs: Repetitive injuries and preventable accidents quickly increase claims and premiums.

-

Downtime and Delays: When tasks depend on physical effort, even small injuries can slow down entire workflows.

-

Reduced Morale and Retention: Workers who feel unsafe or overworked are more likely to burn out or leave.

-

WHS Compliance Risks: Unsafe environments or practices can lead to fines or breaches under Australian regulations.

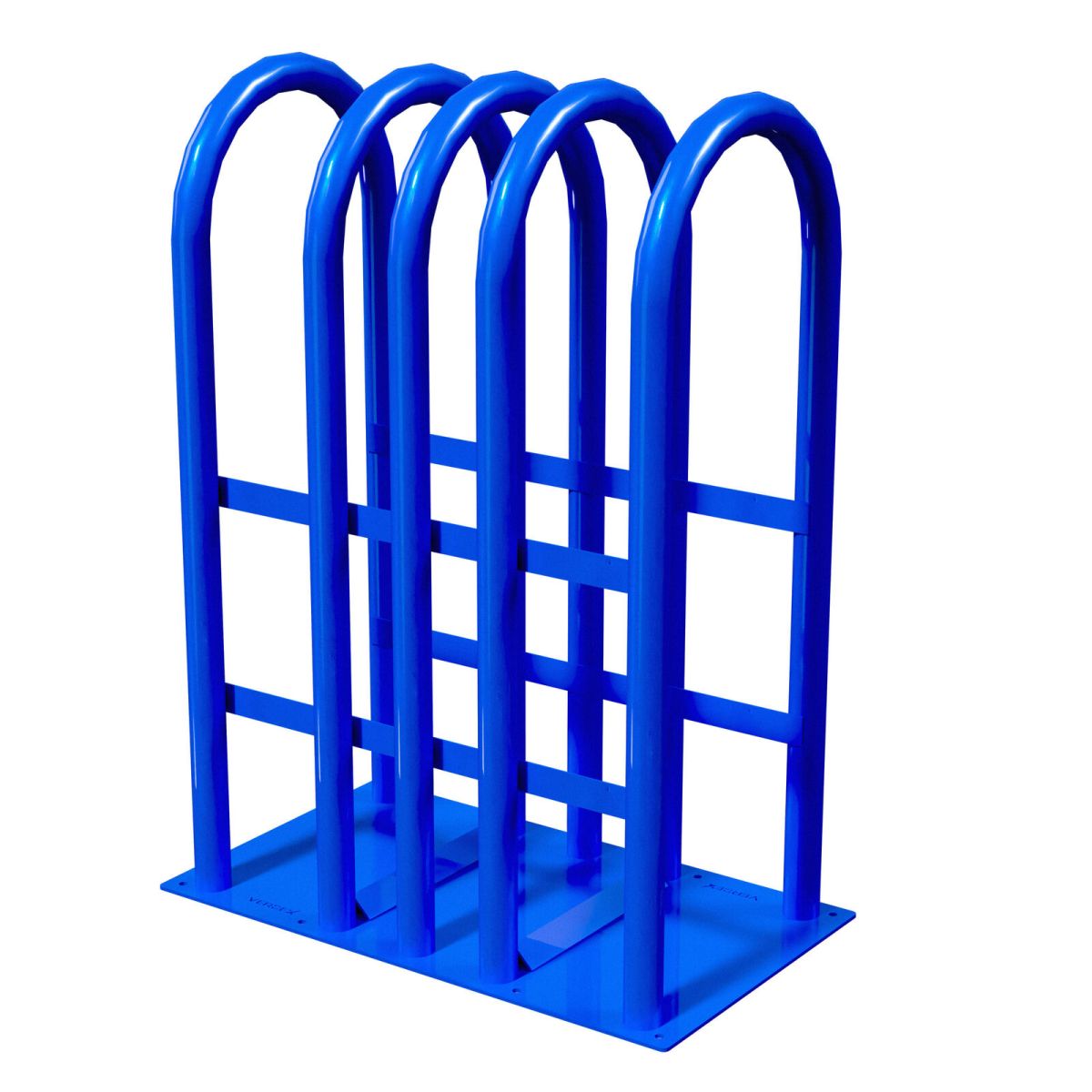

Many of these costs can be avoided by investing in proper materials handling and workplace equipment that removes physical strain and eliminates common hazards. For example, in mechanical and fleet workshops, a Tyre Inflation Enclosure prevents serious blast-related injuries by containing high-pressure tyre failures during inflation, eliminating one of the most dangerous manual risks on site.

Why Equipment Plays a Critical Role in Prevention

Most workplace hazards have one thing in common: they arise when human effort fills the gap left by missing or inadequate equipment. For example, if a pallet lifter isn’t available, workers might bend and lift manually. If the workspace isn’t organised with trolleys or storage cages, materials end up cluttering aisles, creating trip hazards. In retail and supermarket environments, even simple tools like a Shopping Trolley With Baby Seat (242L) help prevent strain by allowing staff to safely transport bulky stock while keeping aisles clear and accessible for customers.

In safety management, this approach is known as relying too heavily on administrative controls (training and behaviour) instead of engineering controls, which are physical systems or tools that remove risks entirely.

Verdex’s range of workplace and materials handling equipment acts as engineering controls, helping Australian businesses take the strain off their workforce and improve compliance at the same time.

How Verdex Equipment Supports Safer Workplaces

Verdex understands that workplace safety isn’t just about meeting standards; it’s about protecting people and ensuring efficiency every day. The company’s extensive range of equipment helps prevent strain and eliminate hazards across every part of the workplace.

Here’s how some of Verdex’s most popular equipment categories contribute to safer, more productive worksites:

1. Trolleys and Hand Trucks

Moving goods manually often leads to back strain or awkward postures. Verdex’s trolleys and hand trucks make it easy to transport heavy or bulky loads safely. From platform trolleys to order-picking models, these tools minimise effort while keeping workflows smooth.

2. Lifting Equipment

Heavy lifting is one of the biggest causes of musculoskeletal injuries in Australian workplaces. Verdex’s range of lift tables, hoists, and scissor lifts removes the need for workers to bend, twist, or strain. Adjustable height features ensure that goods are positioned ergonomically, reducing fatigue and increasing productivity.

3. Conveyor Equipment and Systems

Manual handling between work zones wastes time and increases strain. Conveyors streamline product movement, reducing repetitive lifting and carrying. This not only protects workers but also improves process consistency and throughput.

4. Ladders and Access Equipment

Falls from height are another major workplace hazard. Verdex’s ladders, platforms, and mobile steps provide stable, compliant access to elevated areas. Non-slip surfaces and handrails ensure security and stability while working above ground.

5. Drum Handling Equipment

Drum lifters, tippers, and rotators make handling liquids and chemicals safer and more controlled. This prevents spills, reduces the risk of strain, and ensures hazardous materials are moved and stored in line with WHS regulations.

6. Waste Handling Equipment

Bins, tippers, and waste lifters reduce the physical effort involved in cleaning and waste removal. They prevent workers from lifting or dragging heavy bins and improve hygiene across the site.

7. Dangerous Goods Storage and Spillage

Verdex’s dangerous goods cabinets, bunding, and spill control solutions keep hazardous materials contained and compliant, reducing risks of leaks, exposure, and contamination across the workplace.

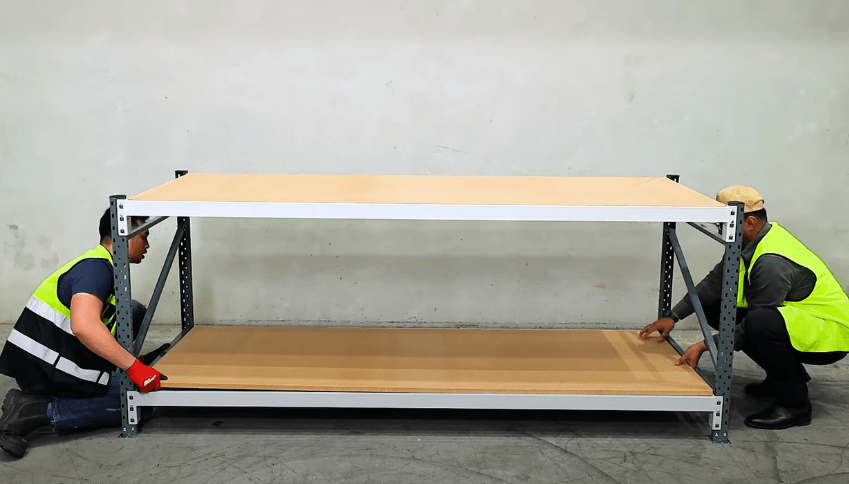

8. Storage and Shelving Equipment

Disorganisation is a silent hazard. Poorly stored goods cause clutter, blocked walkways, and falling risks. Verdex’s heavy-duty shelving, racks, and stillage cages help maintain tidy, efficient, and compliant storage systems, keeping pathways clear and materials secure.

9. Workplace Equipment

Our range of industrial workplace equipment, including benches, workstation accessories, and ergonomic tools, helps reduce strain by improving posture, positioning, and comfort during repetitive or high-precision tasks.

10. Safety Barriers, PPE and Signage

Collisions between people, vehicles, and machinery are common in busy worksites. Verdex’s barriers, PPE and signage create clear separation and communication between pedestrian and vehicle zones, identifying hazards to stay compliant with WHS standards and reducing the risk of impact injuries.

11. Cleaning and Site Supplies

Slippery or cluttered floors are major causes of slips and trips. Verdex’s cleaning and spill control supplies help maintain dry, organised environments, preventing the minor hazards that often lead to major injuries.

12. Construction Equipment

Construction equipment helps crews handle heavy materials safely, stay organised, and maintain compliant worksites, especially in fast-changing or high-risk environments.

Meeting WHS Obligations and Creating a Culture of Prevention

Workplace Health and Safety (WHS) in Australia places a strong emphasis on risk management and proactive prevention. This means businesses must not only identify hazards but also take all reasonable steps to eliminate them where possible.

Verdex equipment helps businesses meet these obligations by implementing practical, physical solutions to common hazards. Instead of relying on workers to adapt to poor conditions, Verdex enables workplaces to design safety into their operations from the start.

Creating a culture of prevention also improves worker engagement and morale. When employees see their employer investing in equipment that makes their job safer and easier, it builds trust and fosters a more positive, productive environment.

Building Safer, Smarter Australian Workplaces

Safety and productivity aren’t opposing goals; they go hand in hand. Verdex helps Australian businesses find that balance through equipment that protects workers while improving operational flow and efficiency.

Beyond material handling, industrial workplace equipment plays a crucial role in eliminating strain and keeping workflows organised. Tools such as workbenches, packing stations, and workstation accessories ensure that tasks are completed at ergonomic heights, with the right support, and without unnecessary bending or reaching.

A great example is our Heavy-Duty Warehouse Packing Bench, which provides a stable, ergonomic surface for packing, sorting, and assembly tasks—helping reduce manual strain and streamline high-volume workflows in warehouses and production areas.

From trolleys and lifting equipment to barriers, shelving, and cleaning systems, Verdex offers end-to-end solutions for building organised, compliant, and safe workplaces. Each product is designed with the challenges of Australian industries in mind, ensuring durability, reliability, and ease of use.

By investing in Verdex solutions, businesses reduce injuries, avoid downtime, and meet WHS requirements, all while boosting overall performance. It’s a smarter, safer, and more sustainable way to work.

Trolleys & Hand Trucks

Trolleys & Hand Trucks Cage Trolleys

Cage Trolleys Cleaning Carts & Trolleys

Cleaning Carts & Trolleys Construction Trolleys

Construction Trolleys Custom Trolleys

Custom Trolleys Hand Trucks & Dollies

Hand Trucks & Dollies Laundry/Linen Trolleys

Laundry/Linen Trolleys Lifting Trolleys

Lifting Trolleys Order Picking Trolleys

Order Picking Trolleys Panel Cart Trolleys

Panel Cart Trolleys Platform Trolleys

Platform Trolleys Powered Trolleys

Powered Trolleys Shelf & Tiered Trolleys

Shelf & Tiered Trolleys Shopping Trolleys

Shopping Trolleys Stainless Steel Trolleys

Stainless Steel Trolleys Tool Trolleys

Tool Trolleys Utility & Service Carts

Utility & Service Carts Lifting & Handling Equipment

Lifting & Handling Equipment Forklift Attachments

Forklift Attachments Jib Attachments

Jib Attachments Lifting Hoists & Pallet Hooks

Lifting Hoists & Pallet Hooks Load Skates & Tow Tugs

Load Skates & Tow Tugs Manual Stackers & Lifters

Manual Stackers & Lifters Pallet Jacks

Pallet Jacks Pallet Lifters

Pallet Lifters Pallet Rotators & Dispenser

Pallet Rotators & Dispenser Powered Pallet Trucks & Electric Lifters

Powered Pallet Trucks & Electric Lifters Scissor Lift Trolleys and Tables

Scissor Lift Trolleys and Tables Conveyor Equipment

Conveyor Equipment Conveyor Frames & Stands

Conveyor Frames & Stands Roller & Skate Conveyors

Roller & Skate Conveyors Ladders & Access Equipment

Ladders & Access Equipment Container & Yard Ramps

Container & Yard Ramps Ladders & Step Stools

Ladders & Step Stools Work Platforms & Crane Cages

Work Platforms & Crane Cages Drum Handling Equipment

Drum Handling Equipment Drum Storage & Bunding

Drum Storage & Bunding Drum Trolleys & Lifters

Drum Trolleys & Lifters Forklift Drum Handling

Forklift Drum Handling Waste Handling & Bins

Waste Handling & Bins Bin Lifters & Tippers

Bin Lifters & Tippers Plastic Waste & Wheelie Bins

Plastic Waste & Wheelie Bins Steel Waste & Tipping Bins

Steel Waste & Tipping Bins Waste Carts

Waste Carts Dangerous Goods Storage & Spillage

Dangerous Goods Storage & Spillage Aerosol Cans Storage Cages

Aerosol Cans Storage Cages Bunded Pallets & Storage

Bunded Pallets & Storage Corrosive Goods Storage Cabinets

Corrosive Goods Storage Cabinets DG Storage & Trolleys

DG Storage & Trolleys Flammable Liquid Cabinets

Flammable Liquid Cabinets Forklift Gas Storage Cages

Forklift Gas Storage Cages Gas Cylinder Storage Bays

Gas Cylinder Storage Bays Site Storage

Site Storage Spill Kits

Spill Kits Shelving & Storage Equipment

Shelving & Storage Equipment Stillage & Transport Cages

Stillage & Transport Cages 750 Series Cage Configurations

750 Series Cage Configurations Heavy Duty Cabinets

Heavy Duty Cabinets Heavy Duty Shelving

Heavy Duty Shelving Mega Bins & Pallets

Mega Bins & Pallets Packing & Workbenches

Packing & Workbenches Parts Trays & Stor-Pak Bins

Parts Trays & Stor-Pak Bins Pegboard & Louvre Panels

Pegboard & Louvre Panels Plastic Bins & Crates

Plastic Bins & Crates Plastic Handling Solutions Bins

Plastic Handling Solutions Bins Plastic Pallets

Plastic Pallets Stack & Nest Bins

Stack & Nest Bins Pallet Racking Accessories

Pallet Racking Accessories Workplace Equipment

Workplace Equipment Modular Workbenches

Modular Workbenches Electric Height-Adjustable Workbenches

Electric Height-Adjustable Workbenches Floor Matting

Floor Matting General Workplace Equipment

General Workplace Equipment Industrial Weighing Scales

Industrial Weighing Scales Packaging Machinery

Packaging Machinery Stationery Cupboards

Stationery Cupboards Storage and Stillage Cages

Storage and Stillage Cages Tool Trolleys

Tool Trolleys Tooling Cabinets

Tooling Cabinets Workshop Fans and Coolers

Workshop Fans and Coolers Safety Barriers, PPE & Signage

Safety Barriers, PPE & Signage Modular Safety Fence System

Modular Safety Fence System Barriers & Bollards

Barriers & Bollards First Aid Equipment

First Aid Equipment Gloves, Knives and PPE

Gloves, Knives and PPE Signage

Signage Cleaning & Site Supplies

Cleaning & Site Supplies Cleaning Equipment

Cleaning Equipment Cleaning Trolleys

Cleaning Trolleys Rubbish Bins

Rubbish Bins Signs & Traffic Supplies

Signs & Traffic Supplies Construction Equipment

Construction Equipment Construction Trolleys

Construction Trolleys Waste Handling

Waste Handling General Site Equipment

General Site Equipment Concrete Equipment

Concrete Equipment Site Storage

Site Storage Lifting Equipment

Lifting Equipment Verdex Specials

Verdex Specials