How to Regain Control of Unorganised Worksites with Reliable Material Handling Equipment

Date Posted:15 December 2025

Take back control of cluttered, inefficient worksites with the material handling systems proven to boost safety and productivity. Discover how the right equipment can eliminate delays, reduce injuries, and keep operations running smoothly.

Verdex Insights: At a Glance

-

The Challenge: Many Australian worksites gradually lose control of their layout as clutter, manual handling, and poor storage systems slow productivity and increase safety risks. Disorganisation leads to blocked aisles, misplaced materials, rising injury rates, and costly WHS compliance issues.

-

The Insight: Most worksite inefficiencies stem from relying on manual labour or outdated methods instead of structured material handling systems. When tools like trolleys, lift tables, stillage cages, and conveyors are missing, workers compensate with unsafe lifting, excessive movement, and inconsistent housekeeping. Restoring order begins with replacing manual strain with reliable handling equipment.

-

The Verdex Solution: Verdex supplies durable, WHS-compliant material handling equipment that brings structure back to busy worksites. Our range of equipment helps businesses reduce clutter, improve safety, and create predictable, efficient workflows. With expert advice and fast nationwide delivery, we support safer, more organised, and more productive worksites across Australia.

How to Regain Control of Unorganised Worksites with Reliable Material Handling Equipment

In many Australian worksites, warehouses, and factories, disorganisation does not happen overnight. It builds up gradually. A tool left out after a long shift, a pallet stored in the wrong place, or waste that is not cleared straight away. Before long, clutter begins to take over. High-capacity waste solutions, such as our Mobile Waste Bin – 500L, help prevent this early clutter from spreading across work areas.

Materials end up scattered, aisles become blocked, and productivity starts to slip. Workers spend valuable time searching for the right tools or moving stock that should already be in place. What begins as a small inconvenience soon becomes a major efficiency and safety issue.

This loss of control often comes down to one thing: inefficient material handling. Relying on manual labour or outdated equipment instead of structured, reliable systems leads to disorganisation, injury risks, and wasted effort. With the right material handling equipment, workplaces can reclaim order, improve safety, and restore productivity.

Why Worksite Organisation Matters for Safety and Efficiency

A well-organised worksite is not just about appearance; it is about performance and protection. When materials and tools are stored correctly, everything has a defined place and work can flow smoothly.

Clear pathways allow safer movement for workers and forklifts. Tools kept in designated areas reduce downtime and prevent damage. Waste is removed efficiently, preventing hazards before they develop.

Disorganisation, on the other hand, introduces risk at every turn. Workers lifting heavy items by hand or squeezing through cluttered aisles are more likely to sustain strains, slips, or crush injuries. Goods stored improperly can topple, spill, or be damaged.

Maintaining order directly supports WHS compliance, as Safe Work Australia emphasises structured workspaces and mechanical aids to minimise manual handling injuries. In short, good organisation protects both people and profits.

Common Causes of Disorganisation in Australian Worksites

Even the most efficient operations can become disorganised over time. Growth, staff turnover, and changing inventory often contribute to the problem. Some of the most common causes include:

-

Lack of proper storage systems, with materials piled wherever space is available rather than in designated zones. Secure storage options such as the Site Tool Cabinet – Double Door help keep tools and equipment contained, reducing clutter and improving site organisation.

-

Heavy reliance on manual handling, where workers lift or move items without the right trolleys, lifts, or conveyors.

-

Poor worksite layout, with frequently used items stored too far from work areas.

-

Insufficient waste management systems that cannot keep up with production volumes.

-

Inconsistent housekeeping routines that allow clutter to build over time.

Recognising these issues is the first step towards solving them. By addressing the underlying causes rather than simply tidying up, sites can achieve lasting improvements in organisation and workflow.

The Hidden Costs of a Messy or Cluttered Workplace

A disorganised worksite is not just unsightly; it is expensive. Every misplaced item, blocked aisle, or inefficient lift adds to operating costs in ways that often go unnoticed.

1. Lost Productivity

When workers spend time searching for tools or moving obstacles, output slows. Over a year, those lost minutes add up to hours of wasted labour.

2. Higher Injury Rates

Cluttered worksites are breeding grounds for slips, trips, and strains. Each incident costs time, money, and sometimes livelihoods.

3. Damaged Goods and Equipment

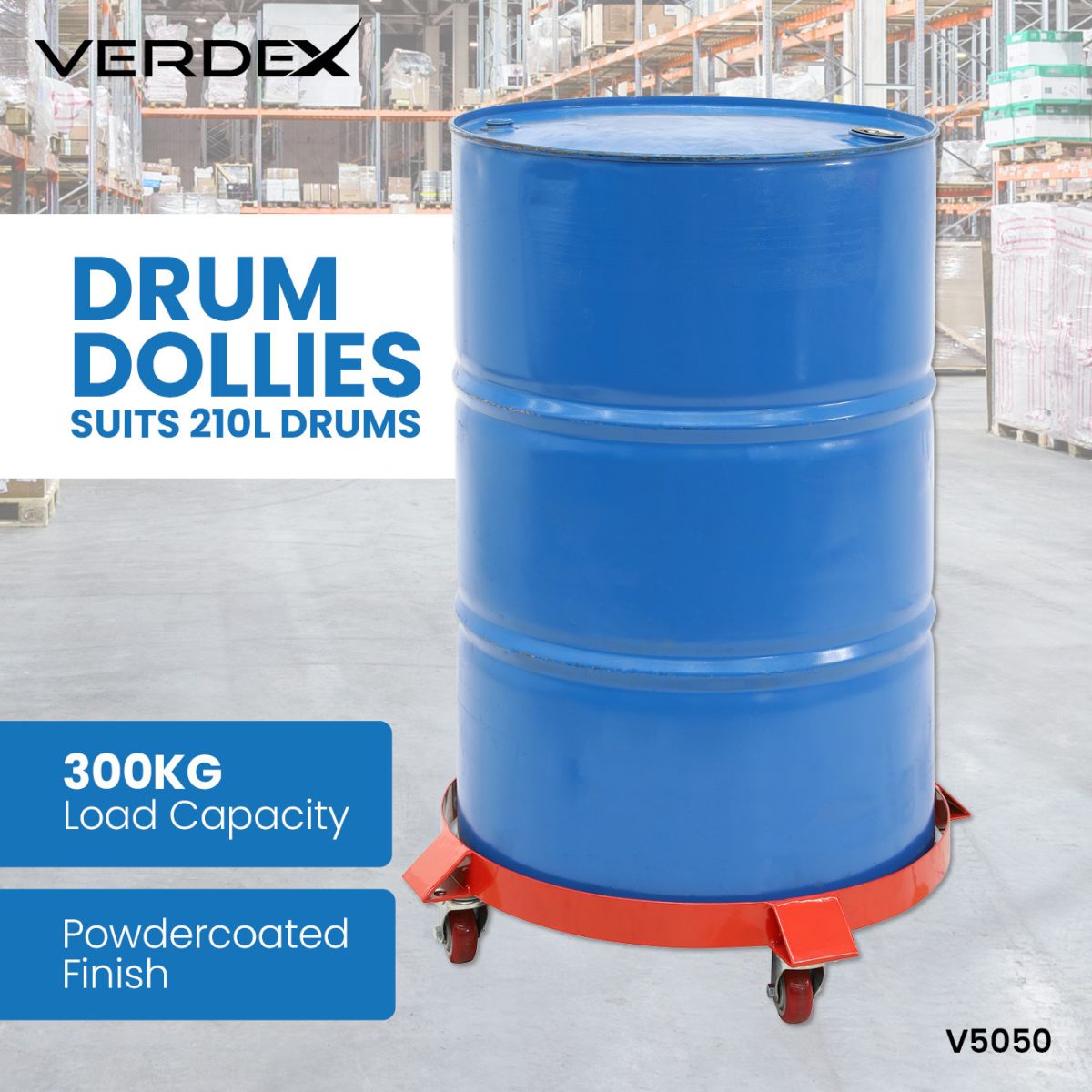

Stacking materials unsafely or using under-rated equipment increases the chance of breakage or contamination. Purpose-built handling tools such as Drum Dollies help workers move heavy drums safely and reduce the risk of drops, spills, or product damage.

4. WHS Compliance Risks

Australian safety standards require clear access ways, safe storage, and risk minimisation. Disorganisation makes it harder to stay compliant and can lead to penalties or claims.

5. Lower Staff Morale

Working in a cluttered, inefficient space is frustrating. It signals poor management and often leads to disengagement or high turnover.

The true cost of disorganisation is more than just downtime; it is the erosion of safety, efficiency, and workplace morale.

How Material Handling Equipment Helps Regain Control

Reliable material handling equipment restores structure, reduces manual labour, and keeps worksites running efficiently. Instead of relying on workers to lift, carry, or reposition heavy loads manually, equipment such as trolleys, stillage cages, conveyors, and lifting tables takes on the strain.

This not only prevents injury but also creates a predictable, streamlined workflow. Workers can focus on value-adding tasks instead of unnecessary handling or transport. This aligns closely with the broader principles outlined in our blog on how Verdex is helping reduce workplace strain and prevent hazards across Australia, where the right equipment plays a central role in eliminating manual effort at the source.

With the right handling systems in place, materials move in a logical sequence, storage areas remain tidy, and waste is cleared efficiently. Every piece of equipment plays a role in reinforcing order, improving safety, and supporting smooth operations.

Key Equipment That Improves Worksite Flow and Safety

No two worksites are identical, but most can benefit from a combination of reliable material handling tools:

Trolleys and Platform Carts

Ideal for transporting boxes, tools, or components, trolleys reduce manual carrying and protect workers from strain injuries.

Stillage and Storage Cages

Provide a safe, stackable way to store bulky or loose materials. They prevent clutter, contain stock, and improve visibility across work areas.

Pallet Jacks and Lift Tables

Essential for managing heavy pallets, these tools allow workers to move and raise loads safely, reducing bending, lifting, and twisting.

Conveyors and Rollers

Streamline the movement of goods between areas, reducing manual transport and maintaining workflow consistency.

Waste Handling Bins and Tipping Hoppers

Efficient waste management keeps production areas clean and hazard-free. Bins and hoppers designed for easy movement support recycling and sustainability efforts.

Access Equipment

Platforms and mobile ladders provide safe access to elevated storage areas, eliminating unsafe climbing or overreaching. Purpose-built options such as the Verdex Access Platform Ladders offer stable, WHS-compliant elevation for picking, stock checks, or maintenance tasks, helping workers reach height safely and confidently.

Practical Tips for Keeping Industrial Worksites Organised

-

Create dedicated storage zones for specific materials or tools, supported by clear signage.

-

Label cages, bins, and racks so workers know exactly where to return items.

-

Establish daily housekeeping routines to clear waste and reset work areas.

-

Conduct weekly audits to identify inefficiencies or misplaced stock.

-

Train staff regularly on safe handling, storage, and equipment use.

-

Use visual management tools such as colour-coded zones or floor markings to guide workflow.

Building these habits into daily operations helps maintain order and efficiency, even during peak workload periods.

Achieving WHS Compliance Through Better Worksite Organisation

Worksite organisation directly supports WHS compliance. Safe Work Australia outlines the importance of hazard control through layout design, mechanical aids, and clear access. A tidy, well-equipped worksite not only protects workers but also aligns with these safety principles. Regular safety assessments also play a key role, as highlighted in our blog on how often workplace safety inspections should occur, helping businesses stay proactive rather than reactive.

Key WHS requirements supported by structured handling systems include:

-

Safe storage and stacking of materials.

-

Clear and unobstructed access routes.

-

Minimisation of manual handling risks.

-

Proper waste disposal and segregation.

By investing in reliable handling equipment, workplaces demonstrate due diligence, reduce risk, and maintain safer, compliant operations. For example, a Packaging / Carton Trolley helps keep packing areas organised and reduces repetitive lifting, supporting safer workflows and ensuring compliance in busy dispatch or replenishment zones.

Create a Safer, More Efficient Worksite with Verdex Solutions

Regaining control of an unorganised worksite does not require a complete overhaul. It begins with the right equipment. Verdex supplies high-quality, Australian-compliant material handling solutions that help workplaces operate smarter and safer.

The Verdex range includes trolleys, stillage cages, lifting tables, conveyors, and access equipment, all designed for durability, efficiency, and WHS compliance. Whether your goal is to clear clutter, move stock faster, or reduce manual handling risks, Verdex provides the tools to make it happen.

By partnering with Verdex, you get:

-

Equipment compliant with Australian Standards for safe, reliable performance.

-

Fast nationwide delivery across major industrial regions.

-

A Price Beat Guarantee for exceptional value.

-

Expert support from a 100% Australian-owned supplier that understands local workplace challenges.

A well-organised worksite is easier to manage, safer for employees, and more profitable overall. With Verdex, regaining control has never been simpler.

Trolleys & Hand Trucks

Trolleys & Hand Trucks Cage Trolleys

Cage Trolleys Cleaning Carts & Trolleys

Cleaning Carts & Trolleys Construction Trolleys

Construction Trolleys Custom Trolleys

Custom Trolleys Hand Trucks & Dollies

Hand Trucks & Dollies Laundry/Linen Trolleys

Laundry/Linen Trolleys Lifting Trolleys

Lifting Trolleys Order Picking Trolleys

Order Picking Trolleys Panel Cart Trolleys

Panel Cart Trolleys Platform Trolleys

Platform Trolleys Powered Trolleys

Powered Trolleys Shelf & Tiered Trolleys

Shelf & Tiered Trolleys Shopping Trolleys

Shopping Trolleys Stainless Steel Trolleys

Stainless Steel Trolleys Tool Trolleys

Tool Trolleys Utility & Service Carts

Utility & Service Carts Lifting & Handling Equipment

Lifting & Handling Equipment Forklift Attachments

Forklift Attachments Jib Attachments

Jib Attachments Lifting Hoists & Pallet Hooks

Lifting Hoists & Pallet Hooks Load Skates & Tow Tugs

Load Skates & Tow Tugs Manual Stackers & Lifters

Manual Stackers & Lifters Pallet Jacks

Pallet Jacks Pallet Lifters

Pallet Lifters Pallet Rotators & Dispenser

Pallet Rotators & Dispenser Powered Pallet Trucks & Electric Lifters

Powered Pallet Trucks & Electric Lifters Scissor Lift Trolleys and Tables

Scissor Lift Trolleys and Tables Conveyor Equipment

Conveyor Equipment Conveyor Frames & Stands

Conveyor Frames & Stands Roller & Skate Conveyors

Roller & Skate Conveyors Ladders & Access Equipment

Ladders & Access Equipment Container & Yard Ramps

Container & Yard Ramps Ladders & Step Stools

Ladders & Step Stools Work Platforms & Crane Cages

Work Platforms & Crane Cages Drum Handling Equipment

Drum Handling Equipment Drum Storage & Bunding

Drum Storage & Bunding Drum Trolleys & Lifters

Drum Trolleys & Lifters Forklift Drum Handling

Forklift Drum Handling Waste Handling & Bins

Waste Handling & Bins Bin Lifters & Tippers

Bin Lifters & Tippers Plastic Waste & Wheelie Bins

Plastic Waste & Wheelie Bins Steel Waste & Tipping Bins

Steel Waste & Tipping Bins Waste Carts

Waste Carts Dangerous Goods Storage & Spillage

Dangerous Goods Storage & Spillage Aerosol Cans Storage Cages

Aerosol Cans Storage Cages Bunded Pallets & Storage

Bunded Pallets & Storage Corrosive Goods Storage Cabinets

Corrosive Goods Storage Cabinets DG Storage & Trolleys

DG Storage & Trolleys Flammable Liquid Cabinets

Flammable Liquid Cabinets Forklift Gas Storage Cages

Forklift Gas Storage Cages Gas Cylinder Storage Bays

Gas Cylinder Storage Bays Site Storage

Site Storage Spill Kits

Spill Kits Shelving & Storage Equipment

Shelving & Storage Equipment Stillage & Transport Cages

Stillage & Transport Cages 750 Series Cage Configurations

750 Series Cage Configurations Heavy Duty Cabinets

Heavy Duty Cabinets Heavy Duty Shelving

Heavy Duty Shelving Mega Bins & Pallets

Mega Bins & Pallets Packing & Workbenches

Packing & Workbenches Parts Trays & Stor-Pak Bins

Parts Trays & Stor-Pak Bins Pegboard & Louvre Panels

Pegboard & Louvre Panels Plastic Bins & Crates

Plastic Bins & Crates Plastic Handling Solutions Bins

Plastic Handling Solutions Bins Plastic Pallets

Plastic Pallets Stack & Nest Bins

Stack & Nest Bins Pallet Racking Accessories

Pallet Racking Accessories Workplace Equipment

Workplace Equipment Modular Workbenches

Modular Workbenches Electric Height-Adjustable Workbenches

Electric Height-Adjustable Workbenches Floor Matting

Floor Matting General Workplace Equipment

General Workplace Equipment Industrial Weighing Scales

Industrial Weighing Scales Packaging Machinery

Packaging Machinery Stationery Cupboards

Stationery Cupboards Storage and Stillage Cages

Storage and Stillage Cages Tool Trolleys

Tool Trolleys Tooling Cabinets

Tooling Cabinets Workshop Fans and Coolers

Workshop Fans and Coolers Safety Barriers, PPE & Signage

Safety Barriers, PPE & Signage Modular Safety Fence System

Modular Safety Fence System Barriers & Bollards

Barriers & Bollards First Aid Equipment

First Aid Equipment Gloves, Knives and PPE

Gloves, Knives and PPE Signage

Signage Cleaning & Site Supplies

Cleaning & Site Supplies Cleaning Equipment

Cleaning Equipment Cleaning Trolleys

Cleaning Trolleys Rubbish Bins

Rubbish Bins Signs & Traffic Supplies

Signs & Traffic Supplies Construction Equipment

Construction Equipment Construction Trolleys

Construction Trolleys Waste Handling

Waste Handling General Site Equipment

General Site Equipment Concrete Equipment

Concrete Equipment Site Storage

Site Storage Lifting Equipment

Lifting Equipment Verdex Specials

Verdex Specials