Process Improvement Methodologies, Tools & Systems

Date Posted:9 July 2025

Discover the tools and systems Australian industries use to boost efficiency and stay compliant with safety standards.

Verdex Insights: At a Glance

-

The Challenge: Many Australian businesses struggle with inefficiencies, safety gaps, and inconsistent processes that impact productivity and compliance. Without structured systems, these issues lead to downtime, waste, and higher operating costs.

-

The Insight: Process improvement methodologies such as 5S, Lean, Six Sigma, and Kaizen help streamline operations, enhance safety, and ensure compliance with Work Health and Safety (WHS) standards. Implementing clear procedures and visual systems reduces risk, improves quality, and drives measurable results.

-

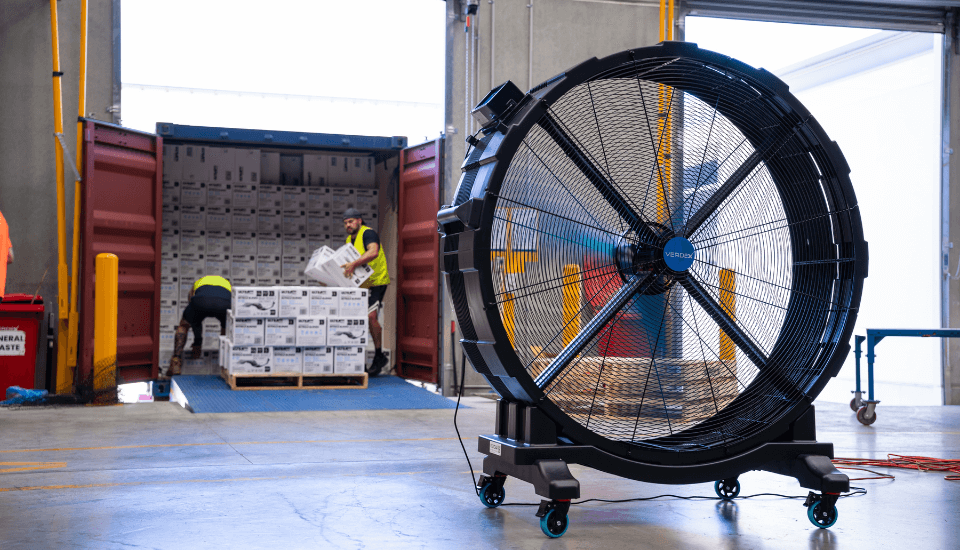

The Verdex Solution: Verdex supports businesses across manufacturing, logistics, warehousing, and construction with practical tools and safety solutions that enable continuous improvement. From visual management systems, signage, and barriers to PPE and first aid equipment, Verdex helps workplaces build safer, more efficient, and compliant operations through structured, sustainable improvement practices.

What Are Process Improvement Methodologies, Tools & Systems?

Process improvement methodologies, tools, and systems are structured approaches used to streamline workplace operations, reduce waste, enhance safety, and boost overall productivity. Together, they help businesses identify inefficiencies, set clear goals, and apply consistent procedures to drive better outcomes.

In Australia, process improvement isn’t just about doing things faster—it’s about doing them smarter and more safely. While many of these methodologies (like Lean or Six Sigma) originated overseas, they’ve been widely adopted across Australian industries such as manufacturing, logistics, warehousing, construction, and healthcare.

Whether you're managing a factory floor or running a small trade business, using the right combination of process improvement methodologies, tools, and systems can help minimise errors, improve efficiency, and support compliance with workplace health and safety standards.

Why Process Improvement Matters

Australian businesses face high labour costs, stringent safety regulations, and increasing competition both locally and globally. Process improvement helps address all three challenges in a practical, measurable way.

By implementing structured systems, businesses can reduce downtime, avoid costly mistakes, and create safer environments for employees. This is especially important in industries where hazards are common and compliance with Safe Work Australia regulations is non-negotiable.

A well-implemented improvement strategy not only increases efficiency, but it can also reduce workers’ compensation claims, increase employee engagement, and help meet environmental and quality obligations. In today’s economic landscape, process improvement is no longer optional, it’s a necessity.

Common Process Improvement Methodologies, Tools & Systems Used in Australia

1. 5S (Five S)

The 5S System stands for:

-

Sort

-

Set in Order

-

Shine

-

Standardise

-

Sustain

It's a foundational methodology used in warehouses, workshops, and logistics environments across Australia.

The goal of 5S is to create a clean, organised, and efficient workspace. By eliminating clutter and standardising workplace layouts, it enhances productivity and safety while reducing time wasted searching for tools or materials.

Benefits include improved workflow, faster turnaround times, enhanced visual management, and lower risk of accidents. For businesses just beginning their process improvement journey, 5S is a simple and effective starting point.

2. Lean Manufacturing

Originally developed by Toyota, Lean Manufacturing focuses on reducing waste and delivering more value to the customer. It emphasises value stream mapping, just-in-time production, and continuous improvement (Kaizen).

In Australian production and operations environments, Lean is used to cut unnecessary processes, minimise inventory, and streamline workflows. It’s especially valuable in manufacturing, automotive, and even service-based industries like healthcare.

The core principle is simple: eliminate anything that doesn’t add value to the end product. Done right, Lean helps reduce costs, improve lead times, and empower frontline employees to improve daily operations.

3. Six Sigma

Six Sigma is a data-driven methodology that focuses on improving quality and consistency by reducing process variation. It uses the DMAIC framework (Define, Measure, Analyse, Improve, Control) to solve complex problems systematically.

Common in larger corporate and manufacturing environments, Six Sigma requires detailed statistical analysis and often involves trained specialists and certifications (White Belt, Yellow Belt, Green Belt, Black Belt, and Master Black Belt). It's ideal for businesses looking to reduce defects, improve customer satisfaction, and increase operational precision.

Although more intensive than some other methodologies, Six Sigma delivers significant ROI when applied to quality-critical operations.

4. Kaizen

Kaizen is the Japanese word for “continuous improvement.” Unlike one-time fixes or large overhauls, Kaizen promotes small, ongoing changes made by all employees every day.

It often works hand-in-hand with Lean and 5S to build a culture where improvement is everyone’s responsibility. In Australian workplaces, Kaizen drives incremental efficiency gains and boosts morale by encouraging staff participation in problem-solving.

From improving tool access in a workshop to reducing paperwork in administration, Kaizen builds long-term resilience through daily action.

5. Visual Management Systems

Visual management systems use tools like colour coding, signage, floor markings, and shadow boards to improve clarity and control in the workplace.

These tools help workers quickly understand what’s happening in an area, such as what goes where, what’s in use, and what needs attention. This improves safety, reduces errors, and enhances accountability.

Australian warehouses and industrial sites widely adopt visual systems to support compliance with Work Health and Safety (WHS) requirements. They're easy to implement and instantly impactful.

6. Safety Management Systems (SMS)

An SMS is a formal framework for managing workplace health and safety. It includes tools like risk assessments, hazard control procedures, training protocols, and incident reporting.

Aligned with Safe Work Australia, a strong SMS is essential for any business that handles machinery, hazardous materials, or physical labour. It not only improves safety but also demonstrates legal compliance and helps reduce liability.

An SMS can be built into your broader process improvement efforts, especially when combined with SOPs and visual controls.

7. ISO Certifications

ISO standards provide internationally recognised frameworks for quality management (ISO 9001), occupational health and safety (ISO 45001), and environmental responsibility (ISO 14001).

In Australia, ISO certification is often required for government tenders and major contracts. These certifications ensure that your systems are robust, auditable, and focused on continual improvement.

While certification involves time and cost, it brings long-term benefits through credibility, improved process control, and better customer trust.

8. Standard Operating Procedures (SOPs)

SOPs are documented instructions that standardise how specific tasks should be performed. They ensure that work is carried out consistently, regardless of who is doing it.

In Australia, SOPs are crucial for training, quality control, and regulatory compliance. They also reduce reliance on “tribal knowledge” and minimise the risk of human error.

By integrating SOPs into daily operations, businesses can build a foundation for growth and quality assurance.

How to Choose the Best System for Your Workplace

Choosing the best methodology depends on several factors:

-

Business size – Smaller teams might start with 5S or SOPs

-

Industry – Manufacturing may benefit from Lean or Six Sigma, while trade businesses might prefer Kaizen and visual systems

-

Team readiness – Change requires buy-in, so consider the culture and training levels

Start small. Introduce visual systems or 5S before scaling up to Lean or ISO frameworks. Whatever the path, align your choice with clear goals: safety, efficiency, quality, or compliance.

Drive Better Results with Smarter Workplace Solutions

Process improvement isn't a one-off task, it’s an ongoing journey. By adopting the right methodology, your business can improve safety, reduce waste, and become more competitive in a challenging market. Start by reviewing your current systems, identifying areas of waste, and involving your team in the improvement process.

Need help getting started? Verdex offers workplace safety tools and expert advice to help you implement systems that work.

Looking to improve how your business runs? Explore our workplace safety equipment and efficiency tools today.

Reach out to us by:

-

Filling out our contact form

-

Emailing us at sales@verdex.com.au

Frequently Asked Questions

What are process improvement methodologies?

They are structured approaches to improving workflows, reducing waste, and boosting workplace efficiency. They include systems like Lean, 5S, Six Sigma, and ISO standards.

Why are process improvement systems important in Australian workplaces?

They help businesses comply with safety regulations, manage high labour costs, and remain competitive by improving productivity and reducing errors.

What industries in Australia use process improvement systems the most?

Process improvement systems are used widely across many sectors in Australia, but they’re most commonly found in industries where efficiency, safety, compliance, or cost control are critical. These include manufacturing, logistics, construction, mining, healthcare, and warehousing.

Do I need special training to implement these systems?

Some systems (like Six Sigma or ISO) require formal training or certification, while others (like 5S or visual management) can be implemented with minimal training.

What is the cost of implementing a process improvement system?

Costs vary—basic systems like 5S are inexpensive, while certifications or consultancy for ISO or Six Sigma involve higher investment but deliver long-term ROI.

Can I combine multiple methodologies in my business?

Yes. Many businesses integrate systems like 5S, Lean, SOPs, and SMS to build a tailored improvement framework suited to their needs and growth stage.

Trolleys & Hand Trucks

Trolleys & Hand Trucks Cage Trolleys

Cage Trolleys Cleaning Carts & Trolleys

Cleaning Carts & Trolleys Construction Trolleys

Construction Trolleys Custom Trolleys

Custom Trolleys Hand Trucks & Dollies

Hand Trucks & Dollies Laundry/Linen Trolleys

Laundry/Linen Trolleys Lifting Trolleys

Lifting Trolleys Order Picking Trolleys

Order Picking Trolleys Panel Cart Trolleys

Panel Cart Trolleys Platform Trolleys

Platform Trolleys Powered Trolleys

Powered Trolleys Shelf & Tiered Trolleys

Shelf & Tiered Trolleys Shopping Trolleys

Shopping Trolleys Stainless Steel Trolleys

Stainless Steel Trolleys Tool Trolleys

Tool Trolleys Utility & Service Carts

Utility & Service Carts Lifting & Handling Equipment

Lifting & Handling Equipment Forklift Attachments

Forklift Attachments Jib Attachments

Jib Attachments Lifting Hoists & Pallet Hooks

Lifting Hoists & Pallet Hooks Load Skates & Tow Tugs

Load Skates & Tow Tugs Manual Stackers & Lifters

Manual Stackers & Lifters Pallet Jacks

Pallet Jacks Pallet Lifters

Pallet Lifters Pallet Rotators & Dispenser

Pallet Rotators & Dispenser Powered Pallet Trucks & Electric Lifters

Powered Pallet Trucks & Electric Lifters Scissor Lift Trolleys and Tables

Scissor Lift Trolleys and Tables Conveyor Equipment

Conveyor Equipment Conveyor Frames & Stands

Conveyor Frames & Stands Roller & Skate Conveyors

Roller & Skate Conveyors Ladders & Access Equipment

Ladders & Access Equipment Container & Yard Ramps

Container & Yard Ramps Ladders & Step Stools

Ladders & Step Stools Work Platforms & Crane Cages

Work Platforms & Crane Cages Drum Handling Equipment

Drum Handling Equipment Drum Storage & Bunding

Drum Storage & Bunding Drum Trolleys & Lifters

Drum Trolleys & Lifters Forklift Drum Handling

Forklift Drum Handling Waste Handling & Bins

Waste Handling & Bins Bin Lifters & Tippers

Bin Lifters & Tippers Plastic Waste & Wheelie Bins

Plastic Waste & Wheelie Bins Steel Waste & Tipping Bins

Steel Waste & Tipping Bins Waste Carts

Waste Carts Dangerous Goods Storage & Spillage

Dangerous Goods Storage & Spillage Aerosol Cans Storage Cages

Aerosol Cans Storage Cages Bunded Pallets & Storage

Bunded Pallets & Storage Corrosive Goods Storage Cabinets

Corrosive Goods Storage Cabinets DG Storage & Trolleys

DG Storage & Trolleys Flammable Liquid Cabinets

Flammable Liquid Cabinets Forklift Gas Storage Cages

Forklift Gas Storage Cages Gas Cylinder Storage Bays

Gas Cylinder Storage Bays Site Storage

Site Storage Spill Kits

Spill Kits Shelving & Storage Equipment

Shelving & Storage Equipment Stillage & Transport Cages

Stillage & Transport Cages 750 Series Cage Configurations

750 Series Cage Configurations Heavy Duty Cabinets

Heavy Duty Cabinets Heavy Duty Shelving

Heavy Duty Shelving Mega Bins & Pallets

Mega Bins & Pallets Packing & Workbenches

Packing & Workbenches Parts Trays & Stor-Pak Bins

Parts Trays & Stor-Pak Bins Pegboard & Louvre Panels

Pegboard & Louvre Panels Plastic Bins & Crates

Plastic Bins & Crates Plastic Handling Solutions Bins

Plastic Handling Solutions Bins Plastic Pallets

Plastic Pallets Stack & Nest Bins

Stack & Nest Bins Pallet Racking Accessories

Pallet Racking Accessories Workplace Equipment

Workplace Equipment Modular Workbenches

Modular Workbenches Electric Height-Adjustable Workbenches

Electric Height-Adjustable Workbenches Floor Matting

Floor Matting General Workplace Equipment

General Workplace Equipment Industrial Weighing Scales

Industrial Weighing Scales Packaging Machinery

Packaging Machinery Stationery Cupboards

Stationery Cupboards Storage and Stillage Cages

Storage and Stillage Cages Tool Trolleys

Tool Trolleys Tooling Cabinets

Tooling Cabinets Workshop Fans and Coolers

Workshop Fans and Coolers Safety Barriers, PPE & Signage

Safety Barriers, PPE & Signage Modular Safety Fence System

Modular Safety Fence System Barriers & Bollards

Barriers & Bollards First Aid Equipment

First Aid Equipment Gloves, Knives and PPE

Gloves, Knives and PPE Signage

Signage Cleaning & Site Supplies

Cleaning & Site Supplies Cleaning Equipment

Cleaning Equipment Cleaning Trolleys

Cleaning Trolleys Rubbish Bins

Rubbish Bins Signs & Traffic Supplies

Signs & Traffic Supplies Construction Equipment

Construction Equipment Construction Trolleys

Construction Trolleys Waste Handling

Waste Handling General Site Equipment

General Site Equipment Concrete Equipment

Concrete Equipment Site Storage

Site Storage Lifting Equipment

Lifting Equipment Verdex Specials

Verdex Specials