Why Warehouses Keep Losing Time at Loading Docks and the Equipment That Stops It

Date Posted:4 December 2025

Many warehouses still struggle with slow loading and unloading due to outdated processes and insufficient materials handling equipment. Here are some common modern dock systems and equipment that help improve speed, safety, and operational flow.

Verdex Insights: At a Glance

-

The Challenge: Australian warehouses continue to lose valuable time at loading docks due to manual handling, mismatched dock heights, congested work zones, and outdated or insufficient equipment. These inefficiencies slow loading and unloading, increase labour fatigue, raise WHS risks, and cut into daily productivity and profitability.

-

The Insight: Small delays compound fast at loading docks. Issues like manual lifting, poor dock alignment, and lack of conveyors or lifting aids turn simple tasks into workflow bottlenecks. Modern loading dock equipment, clear traffic systems, and better ergonomics can transform slow, unsafe loading areas into fast, predictable, and compliant operations.

-

The Verdex Solution: Verdex supplies high-quality, WHS-compliant loading dock equipment engineered for Australian warehouses, including dock levellers, expandable conveyors, pallet jacks, scissor lift trolleys, traffic safety supplies, and access platforms. Our products reduce manual handling, speed up truck turnaround, improve safety, and support smoother freight movement across busy logistics operations. With fast national delivery and expert advice, Verdex helps warehouses reclaim lost time and create safer, more efficient loading docks.

Why Warehouses Keep Losing Time at Loading Docks and the Equipment That Stops It

Efficient loading docks are the heart of every warehouse and logistics operation. They’re the point where goods enter and leave, and every minute saved here can improve the overall productivity of your facility. Yet, despite their importance, many Australian warehouses continue to lose valuable time at their loading docks every single day.

Delays are often caused by outdated processes, underinvestment in material handling equipment, and layouts that no longer suit the demands of modern logistics. These time losses can quietly erode profitability, increase labour costs, and put unnecessary pressure on workers.

The good news is that most of these issues can be solved with simple, cost-effective improvements and the right loading dock equipment.

Two retail specialist colleagues discussing operations in back of warehouse loading dock ↗

The Hidden Time Traps at the Loading Dock

In older or poorly optimised facilities, small inefficiencies quickly add up. A few minutes lost during each truck loading can multiply across dozens of deliveries every day. Let’s look at some of the most common reasons Australian warehouses lose time at their loading docks.

Manual Handling Still Takes Centre Stage

Many warehouses still rely heavily on workers manually lifting, carrying, or unloading goods from trucks. This not only slows down operations but also increases the risk of injuries such as strains and sprains. When workers are fatigued or working in hot conditions, loading and unloading take even longer.

Simple lifting aids like pallet jacks or scissor lift trolleys and tables can dramatically reduce the time spent on manual handling tasks. These tools also reduce fatigue and improve workplace safety.

Docks That Don’t Align with Truck Heights

A surprisingly common issue is that dock heights don’t match the range of vehicles that arrive for loading. When there’s a mismatch, workers are forced to use makeshift ramps, additional lifts, or temporary platforms. Each workaround adds minutes to the process and increases safety risks.

Dock levellers are designed to bridge this gap safely and efficiently. They create a smooth transition between the warehouse floor and the truck bed, allowing forklifts and pallet jacks to move seamlessly between the two.

Congested Dock Areas

Forklifts, pallet jacks, and trolleys often share the same limited space at loading zones. When the area isn’t properly planned, congestion slows everyone down. Poorly marked pathways or limited turning space also increase the chance of collisions or damage.

Installing signs and traffic supplies, or workplace safety equipment such as safety bollards, and designated pedestrian zones can make a major difference. Ladders and Access Equipment like mobile platforms and adjustable loading ramps can also help create a safer and more structured workflow.

Lack of Dock Equipment

Without dock levellers, conveyor equipment, or lifting tables, workers are forced to do more manual handling and take longer routes. These delays might seem minor on their own but can add hours of lost productivity every week.

Expandable conveyors, for instance, make it easy to load and unload loose cartons directly from trucks. Scissor lift trolley tables allow operators to handle heavier items without strain, and pallet jacks make short-distance movement quick and easy. While container ramps help forklifts and other manual handling equipment access shipping containers efficiently and safely.

7 Ways the Right Equipment Can Stop Time Loss at Loading Docks

Modern loading dock setups are built around efficiency. By investing in the right materials handling equipment, warehouses can move more freight in less time while keeping workers safe and compliant with WHS standards.

Here are seven proven ways the right equipment can help.

1. Dock Levellers Eliminate Height Differences

Dock levellers are one of the simplest yet most effective solutions for time loss. They create a level bridge between the dock and the truck, removing the need for manual lifting or temporary ramps. This not only saves time but also reduces equipment wear and improves operator safety.

2. Expandable Conveyors Speed Up Loading

Expandable or flexible conveyors are perfect for facilities handling loose goods or irregularly shaped cartons. They extend directly into the truck trailer, allowing goods to be rolled smoothly into position. Workers spend less time lifting and walking, and more time keeping freight moving.

3. Scissor Lift Trolley Tables Reduce Manual Lifting

Scissor lift trolleys are invaluable when dealing with heavy or awkward items. They allow operators to position goods at a comfortable working height, preventing bending or overreaching. By making handling safer and faster, they reduce fatigue and improve overall productivity.

4. Pallet Jacks Improve Short-Distance Transport

Pallet jacks remain one of the most versatile tools in any warehouse. They make it easy to move loaded pallets quickly across short distances without needing a forklift. Manual and electric models are both efficient, depending on the facility size and workload.

5. Access Equipment Enhances Flexibility

Access platforms, steps, and ladders ensure workers can reach truck decks or elevated areas safely. This prevents risky climbing or makeshift setups that slow down the job. Adjustable platforms can also be repositioned quickly, reducing waiting time between tasks.

6. Dock Shelters and Seals Improve Workflow

Environmental factors can also slow loading operations. Heat, rain, or dust can make work uncomfortable or unsafe. Dock shelters and seals create a more controlled environment, keeping the workspace comfortable and preventing weather-related delays.

7. Clear Signage and Safety Barriers Support Flow

Simple additions such as warning signs, traffic cones, and wheel chocks improve traffic flow and prevent accidents. When workers know where to go and how to move safely, operations run more smoothly and predictably.

Linking Efficiency with WHS Compliance and Smarter Investments

Beyond speed, equipment upgrades also play a major role in improving workplace health and safety. Australian WHS regulations require employers to minimise manual handling risks wherever possible. By providing mechanical aids like pallet jacks, conveyors, and lift tables, businesses demonstrate compliance and protect workers from injury.

Reduced injuries mean fewer lost-time incidents, lower insurance premiums, and a more reliable workforce. In short, a safer warehouse is a more efficient one.

Many managers view equipment purchases as a cost rather than an investment. However, the time saved through efficient loading processes quickly adds up. Faster turnaround means trucks spend less time waiting, labour costs drop, and productivity increases without needing extra staff.

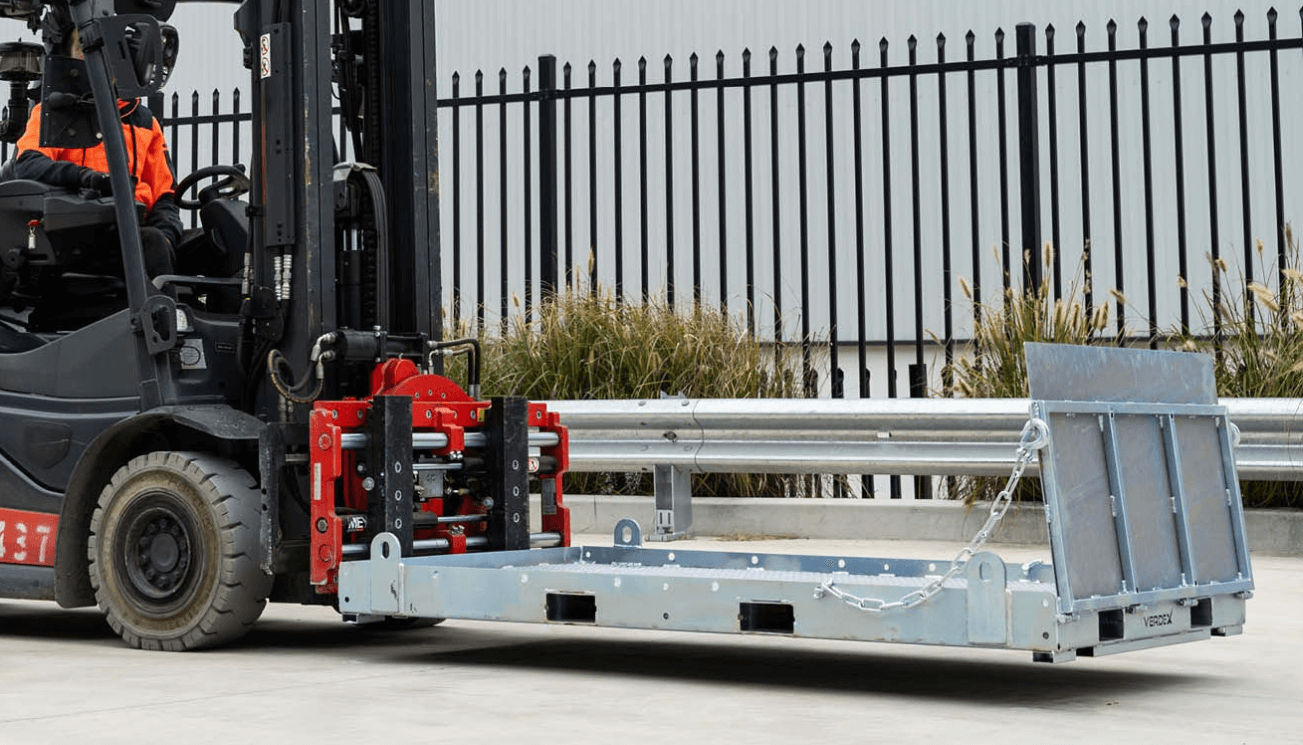

Even small upgrades can deliver major returns within months. Equipment such as dock levellers, expandable conveyors and forklift crane transport platforms pay for themselves by cutting delays, improving safety, and reducing product damage during handling.

Transporting Forklift Crane Transport Platform Folded Ramp ↗

Transporting Forklift Crane Transport Platform Folded Ramp ↗

V4035: Forklift / Crane Transport Platform (with Folding Ramp) ↗

V4035: Forklift / Crane Transport Platform (with Folding Ramp) ↗

Why Choose Verdex for Your Warehouse Equipment

Verdex understands the challenges Australian warehouses face. Our range of high-quality material handling and loading dock equipment is designed to meet local conditions, safety standards, and operational demands.

When you buy from Verdex, you get:

-

Australian Standards compliance on all products.

-

Fast nationwide delivery to keep your operations moving.

-

Price Beat Guarantee, ensuring you get the best value every time.

-

Expert advice from professionals who understand warehouse logistics.

-

Trusted brands built to perform in tough Australian environments.

Upgrading your loading dock setup with Verdex equipment is an investment in speed, safety, and long-term performance.

Verdex warehouse locations in Australia ↗

Trolleys & Hand Trucks

Trolleys & Hand Trucks Cage Trolleys

Cage Trolleys Cleaning Carts & Trolleys

Cleaning Carts & Trolleys Construction Trolleys

Construction Trolleys Custom Trolleys

Custom Trolleys Hand Trucks & Dollies

Hand Trucks & Dollies Laundry/Linen Trolleys

Laundry/Linen Trolleys Lifting Trolleys

Lifting Trolleys Order Picking Trolleys

Order Picking Trolleys Panel Cart Trolleys

Panel Cart Trolleys Platform Trolleys

Platform Trolleys Powered Trolleys

Powered Trolleys Shelf & Tiered Trolleys

Shelf & Tiered Trolleys Shopping Trolleys

Shopping Trolleys Stainless Steel Trolleys

Stainless Steel Trolleys Tool Trolleys

Tool Trolleys Utility & Service Carts

Utility & Service Carts Lifting & Handling Equipment

Lifting & Handling Equipment Forklift Attachments

Forklift Attachments Jib Attachments

Jib Attachments Lifting Hoists & Pallet Hooks

Lifting Hoists & Pallet Hooks Load Skates & Tow Tugs

Load Skates & Tow Tugs Manual Stackers & Lifters

Manual Stackers & Lifters Pallet Jacks

Pallet Jacks Pallet Lifters

Pallet Lifters Pallet Rotators & Dispenser

Pallet Rotators & Dispenser Powered Pallet Trucks & Electric Lifters

Powered Pallet Trucks & Electric Lifters Scissor Lift Trolleys and Tables

Scissor Lift Trolleys and Tables Conveyor Equipment

Conveyor Equipment Conveyor Frames & Stands

Conveyor Frames & Stands Roller & Skate Conveyors

Roller & Skate Conveyors Ladders & Access Equipment

Ladders & Access Equipment Container & Yard Ramps

Container & Yard Ramps Ladders & Step Stools

Ladders & Step Stools Work Platforms & Crane Cages

Work Platforms & Crane Cages Drum Handling Equipment

Drum Handling Equipment Drum Storage & Bunding

Drum Storage & Bunding Drum Trolleys & Lifters

Drum Trolleys & Lifters Forklift Drum Handling

Forklift Drum Handling Waste Handling & Bins

Waste Handling & Bins Bin Lifters & Tippers

Bin Lifters & Tippers Plastic Waste & Wheelie Bins

Plastic Waste & Wheelie Bins Steel Waste & Tipping Bins

Steel Waste & Tipping Bins Waste Carts

Waste Carts Dangerous Goods Storage & Spillage

Dangerous Goods Storage & Spillage Aerosol Cans Storage Cages

Aerosol Cans Storage Cages Bunded Pallets & Storage

Bunded Pallets & Storage Corrosive Goods Storage Cabinets

Corrosive Goods Storage Cabinets DG Storage & Trolleys

DG Storage & Trolleys Flammable Liquid Cabinets

Flammable Liquid Cabinets Forklift Gas Storage Cages

Forklift Gas Storage Cages Gas Cylinder Storage Bays

Gas Cylinder Storage Bays Site Storage

Site Storage Spill Kits

Spill Kits Shelving & Storage Equipment

Shelving & Storage Equipment Stillage & Transport Cages

Stillage & Transport Cages 750 Series Cage Configurations

750 Series Cage Configurations Heavy Duty Cabinets

Heavy Duty Cabinets Heavy Duty Shelving

Heavy Duty Shelving Mega Bins & Pallets

Mega Bins & Pallets Packing & Workbenches

Packing & Workbenches Parts Trays & Stor-Pak Bins

Parts Trays & Stor-Pak Bins Pegboard & Louvre Panels

Pegboard & Louvre Panels Plastic Bins & Crates

Plastic Bins & Crates Plastic Handling Solutions Bins

Plastic Handling Solutions Bins Plastic Pallets

Plastic Pallets Stack & Nest Bins

Stack & Nest Bins Pallet Racking Accessories

Pallet Racking Accessories Workplace Equipment

Workplace Equipment Modular Workbenches

Modular Workbenches Electric Height-Adjustable Workbenches

Electric Height-Adjustable Workbenches Floor Matting

Floor Matting General Workplace Equipment

General Workplace Equipment Industrial Weighing Scales

Industrial Weighing Scales Packaging Machinery

Packaging Machinery Stationery Cupboards

Stationery Cupboards Storage and Stillage Cages

Storage and Stillage Cages Tool Trolleys

Tool Trolleys Tooling Cabinets

Tooling Cabinets Workshop Fans and Coolers

Workshop Fans and Coolers Safety Barriers, PPE & Signage

Safety Barriers, PPE & Signage Modular Safety Fence System

Modular Safety Fence System Barriers & Bollards

Barriers & Bollards First Aid Equipment

First Aid Equipment Gloves, Knives and PPE

Gloves, Knives and PPE Signage

Signage Cleaning & Site Supplies

Cleaning & Site Supplies Cleaning Equipment

Cleaning Equipment Cleaning Trolleys

Cleaning Trolleys Rubbish Bins

Rubbish Bins Signs & Traffic Supplies

Signs & Traffic Supplies Construction Equipment

Construction Equipment Construction Trolleys

Construction Trolleys Waste Handling

Waste Handling General Site Equipment

General Site Equipment Concrete Equipment

Concrete Equipment Site Storage

Site Storage Lifting Equipment

Lifting Equipment Verdex Specials

Verdex Specials