Workplaces That Rely On Safety Barriers

Date Posted:21 July 2025

Not sure if your site needs safety barriers? Think again. Safety barriers help a range of Australian businesses stay compliant, boost productivity, and protect workers.

Verdex Insights: At a Glance

-

The Challenge: Many Australian workplaces face overlapping risks from vehicles, equipment, and foot traffic. Without proper barrier systems, even well-trained teams are vulnerable to collisions, property damage, or WHS breaches.

-

The Insight: Safety barriers create a structured, compliant separation between people, vehicles, and high-risk zones. From warehouses to mining operations, they prevent costly accidents, reduce downtime, and form the foundation of effective traffic management under WHS law.

-

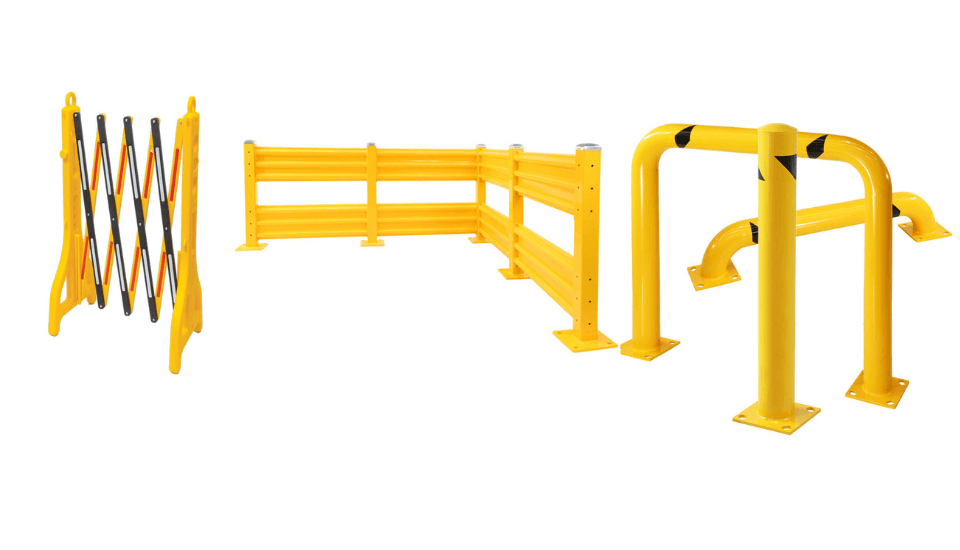

The Verdex Solution: Verdex provides durable, high-visibility safety barriers designed for industrial, commercial, and construction sites. Our range includes guardrails, bollards, wheel stops, and modular barrier systems, all engineered for impact resistance, flexibility, and WHS compliance. Combined with PPE, first aid kits, and workplace safety signage, Verdex delivers complete safety solutions that help businesses protect people, assets, and productivity.

Why Do Certain Workplaces Depend on Safety Barriers?

In many Australian workplaces, hazards such as moving machinery, forklifts, human error, and environmental risks pose significant safety threats.

Safety barriers act as a frontline defence by creating physical separations between people and potential danger zones. They are essential in reducing incidents, protecting infrastructure, and maintaining smoother workflows across industrial, commercial, and construction environments.

More than just preventative, barriers also support compliance with Australia’s Work Health and Safety (WHS) regulations. Employers have a legal "Duty of Care" to manage workplace risks, which includes implementing effective traffic management systems.

Safety barriers are often a key element of these systems, helping facilities meet compliance standards while enhancing overall operational safety.

Key Industries That Rely on Safety Barriers

Warehousing and Logistics

Warehouses depend heavily on safety barriers to manage high levels of traffic between forklifts, pallet jacks, and personnel. Barriers help separate vehicles from pedestrian walkways, reducing collision risks.

Some of our preferred solutions for these work environments include a number of:

Racking protection systems are installed to safeguard shelving from impact damage. Temporary zones can be created using modular barriers to safely conduct picking, packing, or inventory tasks. These measures not only reduce accidents but also ensure efficient warehouse flow.

To further enhance safety and improve overall warehouse functionality, it’s important to complement these systems with the right workplace safety equipment supplies.

Manufacturing and Production Facilities

In fast-paced manufacturing environments, machine guards and modular fencing help shield employees from high-speed automation, robotics, and conveyor systems.

Physical separation reduces the chance of accidental contact, especially in automated or semi-automated production lines.

Safety barriers also help with zoning, allowing clear demarcation of work areas for tasks such as material loading, assembly, or quality checks.

Construction Sites

Construction areas are dynamic and inherently hazardous. Temporary pedestrian barriers and high-visibility bollards, such as large fixed safety bollards and t-top plastic bollards, help guide workers and visitors safely around danger zones.

These barriers comply with strict WHS codes relevant to construction and demolition activities. Modular systems are ideal for construction sites because they can be quickly deployed or reconfigured as the layout evolves.

Transport Depots and Loading Docks

Loading docks and transport depots are hot spots for accidents, especially during truck reversing and forklift operations. Forklift wheel stops and safety guardrail fencing around bays and entrances protect equipment, buildings and people.

Bollards provide impact resistance in high-traffic areas, and clearly marked pedestrian walkways offer a safer path for drivers and dock workers.

Food and Beverage Processing

In these hygiene-sensitive environments, stainless steel or food-grade safety barriers are used to segregate workers from hazardous equipment like slicers or fillers. These barriers are easy to clean and resistant to moisture or bacteria, supporting sanitary compliance. Modular designs make it easy to adapt to layout changes or regular washdowns.

Mining and Heavy Industry

Safety barriers in mining must withstand extreme impact and harsh conditions, including heat, dust, and moisture.

Heavy-duty bollards and reinforced guardrails are used to protect both people and machinery near crushers, explosive zones, or heavy equipment areas.

Car Parks

Even outside of industrial zones, car parks rely on bollards, wheel stops, and pedestrian barriers to organise vehicle movement and reduce risk to pedestrians. These systems improve visibility, reduce accidents, and guide traffic safely.

What Makes Safety Barriers So Valuable in These Settings?

Safety barriers are more than physical dividers—they’re strategic tools that help businesses operate more safely and efficiently. They reduce workplace downtime caused by accidents, infrastructure damage, or near-miss incidents. Barriers also help sites remain compliant with WHS and ISO safety standards, avoiding legal or financial penalties.

To support a comprehensive safety strategy, barriers are often used alongside other critical solutions such as first aid equipment, PPE clothing and safety gear, and clear workplace signage. They each play a vital role in protecting employees and maintaining a compliant, high-functioning site. When workers feel protected by well-integrated safety systems, confidence and morale increase, often leading to better productivity.

Long-term, investing in quality safety barriers can reduce costs associated with damaged equipment, medical expenses, and insurance claims. In environments where safety, compliance, and operational continuity are non-negotiable, safety barriers prove to be an invaluable asset.

Internal Safety Reviews: When to Reassess Your Barrier Systems

Workplace safety is not a set-and-forget responsibility. Regular reviews ensure your safety systems remain effective as your site evolves. Some steps to follow include:

-

Consider reassessing your barriers when your facility expands, new machinery is installed, or pedestrian and vehicle traffic patterns change.

-

After any incident report or near-miss event, a safety review can identify gaps that need immediate attention.

-

Annual WHS audits are also key triggers for checking barrier placement, visibility, and condition.

-

Other reasons to re-evaluate include shifts in regulatory requirements, the introduction of automated equipment, or changes in operating hours.

-

Periodic reviews help future-proof your workplace and ensure continued compliance.

How Verdex Supports Australian Workplaces with Barrier Systems

At Verdex, we specialise in high-quality safety barrier solutions tailored for Australian workplaces. Our extensive product range includes guardrails, heavy-duty bollards, pedestrian barriers, and modular fencing systems.

Whether you need fixed or flexible options, our products are made from durable materials designed to handle high-impact zones and meet WHS compliance. We also offer custom solutions and a range of materials handling equipment to match your site’s unique safety challenges.

With national delivery, expert support, and a trusted supplier network, Verdex makes it easy to upgrade your safety systems with confidence.

For more information, speak to our friendly team by:

-

Emailing us at sales@verdex.com.au

-

Or fill out our contact form

FAQs

How do I know if my worksite is compliant?

A WHS professional or safety auditor can assess your facility to ensure your traffic management systems and safety barriers meet national standards. Regular audits and safety reviews are highly recommended.

Are safety barriers only for industrial settings?

No. Safety barriers are used across commercial, retail, and public environments such as car parks, healthcare facilities, and schools, as well as traditional industrial zones.

Can safety barriers be moved or reconfigured?

Yes. Many modern barrier systems are modular, allowing you to reconfigure them as your layout or safety needs change. This is especially useful in growing or temporary workspaces.

Do different industries need different types of safety barriers?

Absolutely. Each industry faces unique hazards. For example, food processing needs hygienic barriers, while mining requires impact-resistant, weatherproof systems.

What colour should my safety barriers be?

In most cases, bright colours like yellow or orange are used to maximise visibility. Specific colour standards may apply depending on the barrier's function or industry guidelines.

Trolleys & Hand Trucks

Trolleys & Hand Trucks Cage Trolleys

Cage Trolleys Cleaning Carts & Trolleys

Cleaning Carts & Trolleys Construction Trolleys

Construction Trolleys Custom Trolleys

Custom Trolleys Hand Trucks & Dollies

Hand Trucks & Dollies Laundry/Linen Trolleys

Laundry/Linen Trolleys Lifting Trolleys

Lifting Trolleys Order Picking Trolleys

Order Picking Trolleys Panel Cart Trolleys

Panel Cart Trolleys Platform Trolleys

Platform Trolleys Powered Trolleys

Powered Trolleys Shelf & Tiered Trolleys

Shelf & Tiered Trolleys Shopping Trolleys

Shopping Trolleys Stainless Steel Trolleys

Stainless Steel Trolleys Tool Trolleys

Tool Trolleys Utility & Service Carts

Utility & Service Carts Lifting & Handling Equipment

Lifting & Handling Equipment Forklift Attachments

Forklift Attachments Jib Attachments

Jib Attachments Lifting Hoists & Pallet Hooks

Lifting Hoists & Pallet Hooks Load Skates & Tow Tugs

Load Skates & Tow Tugs Manual Stackers & Lifters

Manual Stackers & Lifters Pallet Jacks

Pallet Jacks Pallet Lifters

Pallet Lifters Pallet Rotators & Dispenser

Pallet Rotators & Dispenser Powered Pallet Trucks & Electric Lifters

Powered Pallet Trucks & Electric Lifters Scissor Lift Trolleys and Tables

Scissor Lift Trolleys and Tables Conveyor Equipment

Conveyor Equipment Conveyor Frames & Stands

Conveyor Frames & Stands Roller & Skate Conveyors

Roller & Skate Conveyors Ladders & Access Equipment

Ladders & Access Equipment Container & Yard Ramps

Container & Yard Ramps Ladders & Step Stools

Ladders & Step Stools Work Platforms & Crane Cages

Work Platforms & Crane Cages Drum Handling Equipment

Drum Handling Equipment Drum Storage & Bunding

Drum Storage & Bunding Drum Trolleys & Lifters

Drum Trolleys & Lifters Forklift Drum Handling

Forklift Drum Handling Waste Handling & Bins

Waste Handling & Bins Bin Lifters & Tippers

Bin Lifters & Tippers Plastic Waste & Wheelie Bins

Plastic Waste & Wheelie Bins Steel Waste & Tipping Bins

Steel Waste & Tipping Bins Waste Carts

Waste Carts Dangerous Goods Storage & Spillage

Dangerous Goods Storage & Spillage Aerosol Cans Storage Cages

Aerosol Cans Storage Cages Bunded Pallets & Storage

Bunded Pallets & Storage Corrosive Goods Storage Cabinets

Corrosive Goods Storage Cabinets DG Storage & Trolleys

DG Storage & Trolleys Flammable Liquid Cabinets

Flammable Liquid Cabinets Forklift Gas Storage Cages

Forklift Gas Storage Cages Gas Cylinder Storage Bays

Gas Cylinder Storage Bays Site Storage

Site Storage Spill Kits

Spill Kits Shelving & Storage Equipment

Shelving & Storage Equipment Stillage & Transport Cages

Stillage & Transport Cages 750 Series Cage Configurations

750 Series Cage Configurations Heavy Duty Cabinets

Heavy Duty Cabinets Heavy Duty Shelving

Heavy Duty Shelving Mega Bins & Pallets

Mega Bins & Pallets Packing & Workbenches

Packing & Workbenches Parts Trays & Stor-Pak Bins

Parts Trays & Stor-Pak Bins Pegboard & Louvre Panels

Pegboard & Louvre Panels Plastic Bins & Crates

Plastic Bins & Crates Plastic Handling Solutions Bins

Plastic Handling Solutions Bins Plastic Pallets

Plastic Pallets Stack & Nest Bins

Stack & Nest Bins Pallet Racking Accessories

Pallet Racking Accessories Workplace Equipment

Workplace Equipment Modular Workbenches

Modular Workbenches Electric Height-Adjustable Workbenches

Electric Height-Adjustable Workbenches Floor Matting

Floor Matting General Workplace Equipment

General Workplace Equipment Industrial Weighing Scales

Industrial Weighing Scales Packaging Machinery

Packaging Machinery Stationery Cupboards

Stationery Cupboards Storage and Stillage Cages

Storage and Stillage Cages Tool Trolleys

Tool Trolleys Tooling Cabinets

Tooling Cabinets Workshop Fans and Coolers

Workshop Fans and Coolers Safety Barriers, PPE & Signage

Safety Barriers, PPE & Signage Modular Safety Fence System

Modular Safety Fence System Barriers & Bollards

Barriers & Bollards First Aid Equipment

First Aid Equipment Gloves, Knives and PPE

Gloves, Knives and PPE Signage

Signage Cleaning & Site Supplies

Cleaning & Site Supplies Cleaning Equipment

Cleaning Equipment Cleaning Trolleys

Cleaning Trolleys Rubbish Bins

Rubbish Bins Signs & Traffic Supplies

Signs & Traffic Supplies Construction Equipment

Construction Equipment Construction Trolleys

Construction Trolleys Waste Handling

Waste Handling General Site Equipment

General Site Equipment Concrete Equipment

Concrete Equipment Site Storage

Site Storage Lifting Equipment

Lifting Equipment Verdex Specials

Verdex Specials