Understanding The Different Types Of Conveyors In Workplaces

Date Posted:15 April 2024

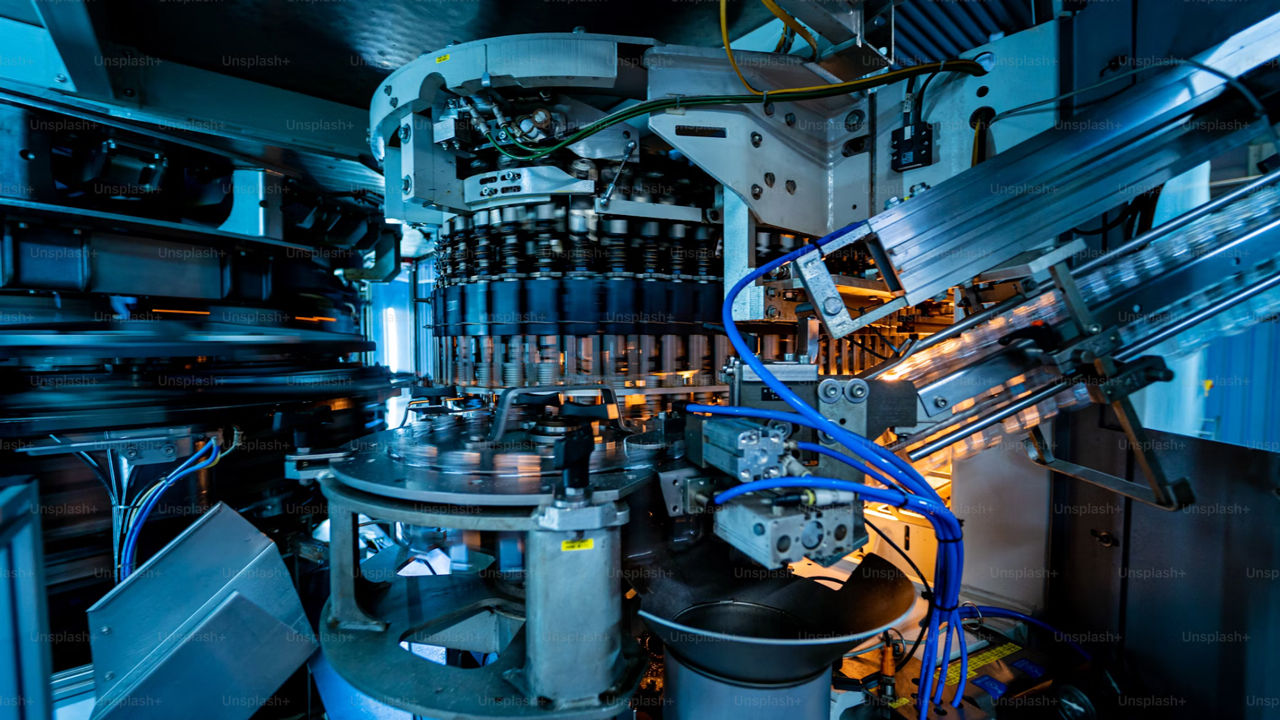

In modern workplaces, the role of conveyors cannot be overstated. These systems streamline the movement of materials, significantly boosting efficiency, safety and productivity. Conveyors eliminate the need for manual transportation, reducing the risk of workplace injuries and allowing for the seamless operation of various industrial tasks.

From small parts to large pallets, conveyors ensure that materials are moved swiftly and securely, optimising workflow and enhancing operational efficiency. In this blog post, let’s take a look at the different types of conveyors, as well as the considerations one should make when selecting the right conveyor for their workplace.

What are the different types of conveyors?

Here are the different types of conveyor belts that can be found in workplaces:

- Skate wheel conveyors — Ideal for lightweight loads, skate wheel conveyors consist of small wheels attached to a series of axles and are excellent for moving items that are flat on the bottom. Their simple design makes them not only cost-effective but also highly flexible and easy to install and reconfigure as needed.

- Expanding skate conveyors — These conveyors extend like a telescope to suit various distances and are perfect for temporary setups or dynamic work environments. They're highly adaptable, making them suitable for loading and unloading areas or linking different sections of a workflow.

- Expanding roller conveyors — Featuring rollers that allow for the smooth movement of goods, these conveyors can adjust in length and are designed for more substantial items than skate wheel variants. They're particularly useful in shipping and receiving areas, offering flexibility in how materials are routed through a space.

- Electric expanding roller conveyors — Combining the adaptability of expanding conveyors with the power of electric motors, these conveyors automate the movement process, enhancing efficiency further. They are ideal for heavier loads and can significantly reduce manual handling, making them a smart choice for modern, high-volume workplaces.

- Pneumatic conveyors — Pneumatic conveyors use air pressure or vacuum to transport materials through a system of tubes, making them ideal for moving powders, granules and other small or fine materials. They offer a clean, safe and efficient way to move products in various industries, including food, pharmaceuticals and manufacturing..

.jpg)

Choosing the right conveyor for your workplace

When integrating conveyors into your workplace, it's crucial to consider these key factors to guide your selection:

- Material characteristics — Understand the physical properties of the materials you intend to move. Different types of conveyors and conveyor belts are designed to handle specific materials, from lightweight goods to heavy-duty products.

- Operational needs — Assess your operational requirements, including speed, volume and the direction of material movement. This will help determine the types of conveyor belts or types of conveyors suitable for your application.

- Space constraints — Evaluate the available space in your workplace. Some conveyors, like expanding skate and roller conveyors, offer flexibility in layout and can be adjusted to fit limited spaces.

- Maintenance and durability — Consider the maintenance needs and durability of the conveyor system. Electric expanding roller conveyors, for example, may require more maintenance but can handle heavier loads efficiently.

- Safety features — Prioritise conveyors with built-in safety features to protect your workforce and materials.

- Budget and return on investment (ROI) — Be sure to balance your budget with the potential return on investment. While some conveyor systems may have higher upfront costs, their efficiency and durability can offer long-term savings.

You can learn more about the Role of Conveyors in Streamlining Workplace Operations in our other blog.

Take your workplace to the next level with Verdex Equipment

Conveyors play a critical role in modern workplaces by enhancing efficiency, safety and productivity. Verdex Equipment is proud to supply top-quality, durable and easy-to-install conveyors to various sectors across Australia, including hospitals, schools and workplaces. Our range of conveyors is designed to meet the diverse needs of these environments, ensuring materials are moved swiftly and securely.

Apart from conveyors, Verdex Equipment also offers an extensive selection of industrial workplace solutions, including trolleys and hand trucks, lifting equipment and warehouse and storage equipment. Each product in our catalogue is crafted with quality and reliability in mind, providing you with the tools necessary to optimise your operations. We also provide free delivery to Sydney, Brisbane, Melbourne and Adelaide metro areas.

To explore the full range of options and learn how our equipment can benefit your workplace, please feel free to contact us. Our team is ready to assist you in selecting the perfect solutions to meet your operational needs.

Trolleys & Hand Trucks

Trolleys & Hand Trucks Cage Trolleys

Cage Trolleys Cleaning Carts & Trolleys

Cleaning Carts & Trolleys Construction Trolleys

Construction Trolleys Custom Trolleys

Custom Trolleys Hand Trucks & Dollies

Hand Trucks & Dollies Laundry/Linen Trolleys

Laundry/Linen Trolleys Lifting Trolleys

Lifting Trolleys Order Picking Trolleys

Order Picking Trolleys Panel Cart Trolleys

Panel Cart Trolleys Platform Trolleys

Platform Trolleys Powered Trolleys

Powered Trolleys Shelf & Tiered Trolleys

Shelf & Tiered Trolleys Shopping Trolleys

Shopping Trolleys Stainless Steel Trolleys

Stainless Steel Trolleys Tool Trolleys

Tool Trolleys Utility & Service Carts

Utility & Service Carts Lifting & Handling Equipment

Lifting & Handling Equipment Forklift Attachments

Forklift Attachments Jib Attachments

Jib Attachments Lifting Hoists & Pallet Hooks

Lifting Hoists & Pallet Hooks Load Skates & Tow Tugs

Load Skates & Tow Tugs Manual Stackers & Lifters

Manual Stackers & Lifters Pallet Jacks

Pallet Jacks Pallet Lifters

Pallet Lifters Pallet Rotators & Dispenser

Pallet Rotators & Dispenser Powered Pallet Trucks & Electric Lifters

Powered Pallet Trucks & Electric Lifters Scissor Lift Trolleys and Tables

Scissor Lift Trolleys and Tables Conveyor Equipment

Conveyor Equipment Conveyor Frames & Stands

Conveyor Frames & Stands Roller & Skate Conveyors

Roller & Skate Conveyors Ladders & Access Equipment

Ladders & Access Equipment Container & Yard Ramps

Container & Yard Ramps Ladders & Step Stools

Ladders & Step Stools Work Platforms & Crane Cages

Work Platforms & Crane Cages Drum Handling Equipment

Drum Handling Equipment Drum Storage & Bunding

Drum Storage & Bunding Drum Trolleys & Lifters

Drum Trolleys & Lifters Forklift Drum Handling

Forklift Drum Handling Waste Handling & Bins

Waste Handling & Bins Bin Lifters & Tippers

Bin Lifters & Tippers Plastic Waste & Wheelie Bins

Plastic Waste & Wheelie Bins Steel Waste & Tipping Bins

Steel Waste & Tipping Bins Waste Carts

Waste Carts Dangerous Goods Storage & Spillage

Dangerous Goods Storage & Spillage Aerosol Cans Storage Cages

Aerosol Cans Storage Cages Bunded Pallets & Storage

Bunded Pallets & Storage Corrosive Goods Storage Cabinets

Corrosive Goods Storage Cabinets DG Storage & Trolleys

DG Storage & Trolleys Flammable Liquid Cabinets

Flammable Liquid Cabinets Forklift Gas Storage Cages

Forklift Gas Storage Cages Gas Cylinder Storage Bays

Gas Cylinder Storage Bays Site Storage

Site Storage Spill Kits

Spill Kits Shelving & Storage Equipment

Shelving & Storage Equipment Stillage & Transport Cages

Stillage & Transport Cages 750 Series Cage Configurations

750 Series Cage Configurations Heavy Duty Cabinets

Heavy Duty Cabinets Heavy Duty Shelving

Heavy Duty Shelving Mega Bins & Pallets

Mega Bins & Pallets Packing & Workbenches

Packing & Workbenches Parts Trays & Stor-Pak Bins

Parts Trays & Stor-Pak Bins Pegboard & Louvre Panels

Pegboard & Louvre Panels Plastic Bins & Crates

Plastic Bins & Crates Plastic Handling Solutions Bins

Plastic Handling Solutions Bins Plastic Pallets

Plastic Pallets Stack & Nest Bins

Stack & Nest Bins Pallet Racking Accessories

Pallet Racking Accessories Workplace Equipment

Workplace Equipment Modular Workbenches

Modular Workbenches Electric Height-Adjustable Workbenches

Electric Height-Adjustable Workbenches Floor Matting

Floor Matting General Workplace Equipment

General Workplace Equipment Industrial Weighing Scales

Industrial Weighing Scales Packaging Machinery

Packaging Machinery Stationery Cupboards

Stationery Cupboards Storage and Stillage Cages

Storage and Stillage Cages Tool Trolleys

Tool Trolleys Tooling Cabinets

Tooling Cabinets Workshop Fans and Coolers

Workshop Fans and Coolers Safety Barriers, PPE & Signage

Safety Barriers, PPE & Signage Modular Safety Fence System

Modular Safety Fence System Barriers & Bollards

Barriers & Bollards First Aid Equipment

First Aid Equipment Gloves, Knives and PPE

Gloves, Knives and PPE Signage

Signage Cleaning & Site Supplies

Cleaning & Site Supplies Cleaning Equipment

Cleaning Equipment Cleaning Trolleys

Cleaning Trolleys Rubbish Bins

Rubbish Bins Signs & Traffic Supplies

Signs & Traffic Supplies Construction Equipment

Construction Equipment Construction Trolleys

Construction Trolleys Waste Handling

Waste Handling General Site Equipment

General Site Equipment Concrete Equipment

Concrete Equipment Site Storage

Site Storage Lifting Equipment

Lifting Equipment Verdex Specials

Verdex Specials